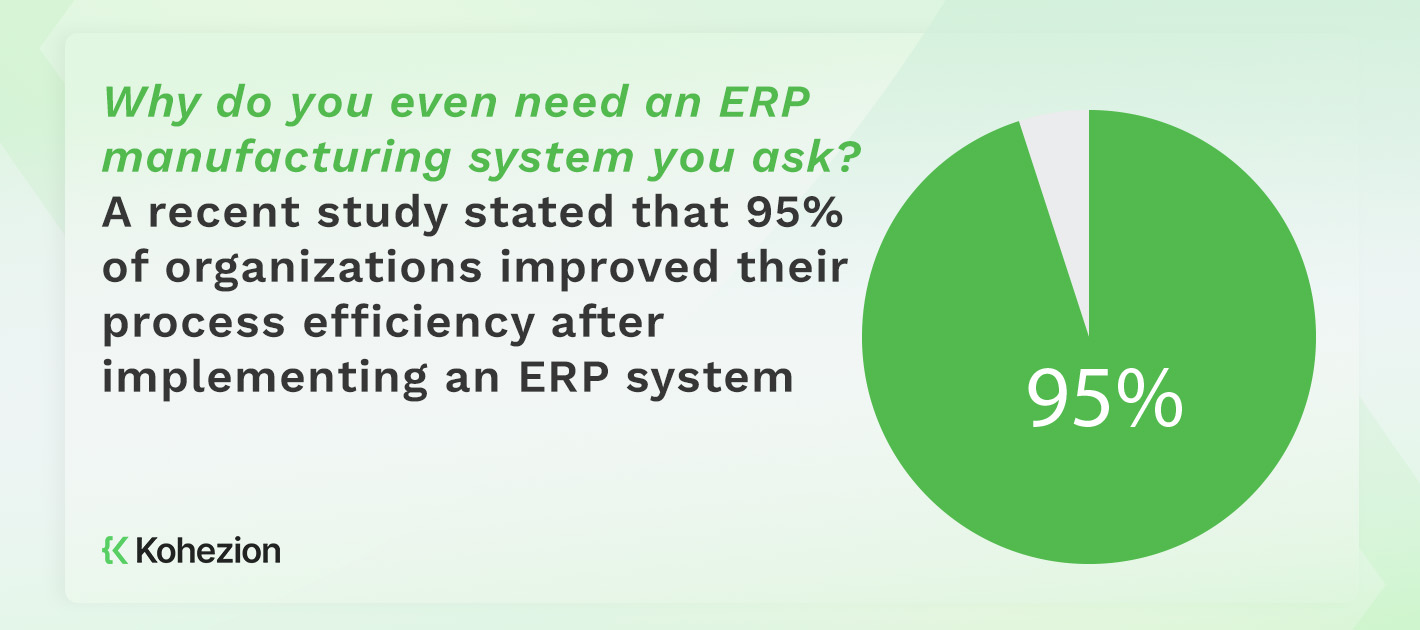

The right Enterprise Resource Planning (ERP) software can greatly improve manufacturing efficiency. But why do you even need an ERP manufacturing system? A recent study stated that 95% of organizations improved their process efficiency after implementing an ERP system.

In this article, we will review the best ERP systems for manufacturing businesses. We aim to guide you through the selection process with expert insights and top-notch comparative analysis.

We'll buid your first application for you. At no extra cost.

Let us build your first business application for free. Go from an idea to an application in under 2 weeks.

What is Manufacturing ERP Software?

Manufacturing ERP (Enterprise Resource Planning) software is a comprehensive system that combines and synchronizes all aspects of manufacturing operations. It integrates various functional areas like financial management, production planning, scheduling, shop floor control, inventory management, and warehouse management.

Specifically catered to meet manufacturers' requirements, the software offers insights, control, and analytics to improve efficiency, reduce costs, and increase profitability. This tool is designed for metal, food, automotive, textile manufacturing, and more industries.

Why is Having Manufacturing ERP Software Important?

Manufacturing ERP software plays a crucial role in the success of manufacturing companies. It helps businesses manage their operations efficiently by providing tools for tasks like inventory management, production planning, and order tracking. This software allows companies to streamline processes, reduce errors, and improve overall efficiency.

Having a centralized system to monitor and control all aspects of manufacturing helps businesses make better decisions and optimize their resources effectively. This leads to increased productivity, reduced costs, and improved customer satisfaction, making manufacturing ERP software essential for the success of manufacturing companies.

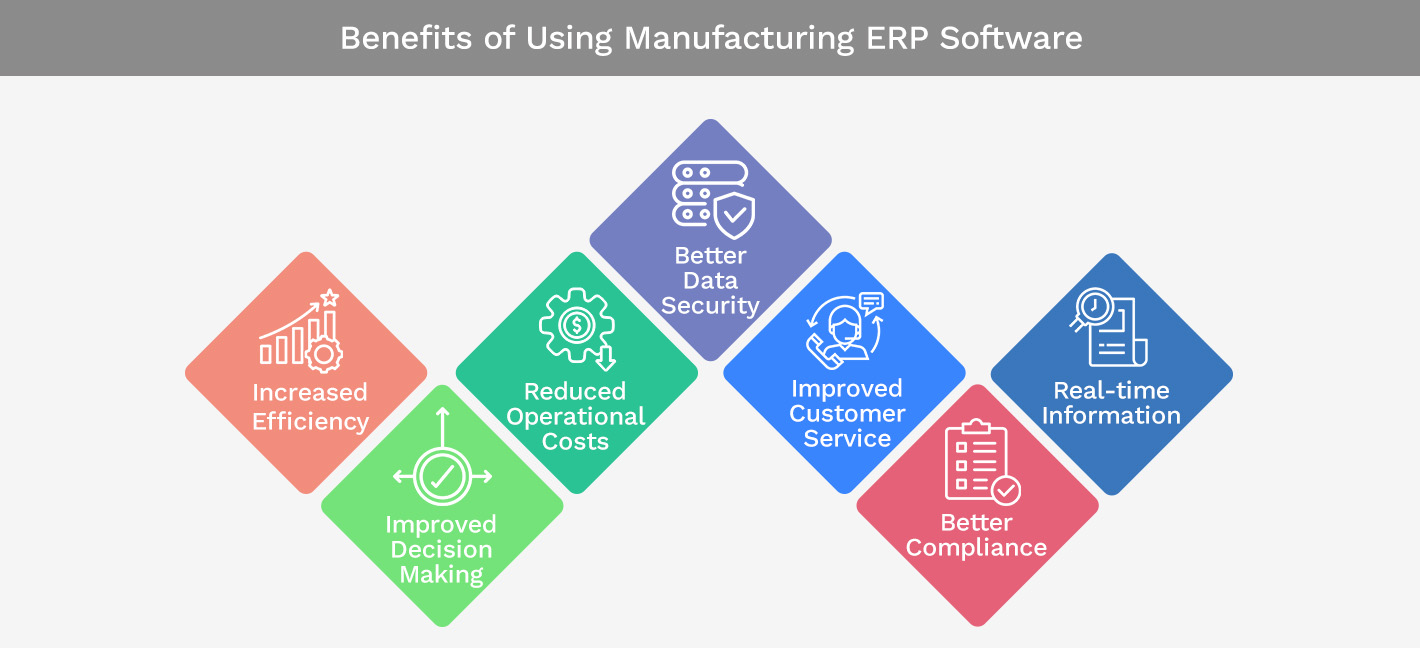

Benefits of Using Manufacturing ERP Software

Implementing manufacturing ERP software holds numerous benefits for your business in terms of streamlining operations, ensuring efficiency, and driving growth. Here are some of the key benefits such software can offer:

Increased Efficiency

An ERP system automates your business processes, reducing the need for repetitive manual tasks and enhancing efficiency across all business operations.

Improved Decision-Making

ERP software collects and analyzes business data, providing insightful analytics that can drive informed decision-making and help improve strategic planning and operational control.

Reduced Operational Costs

ERP software streamlines business processes and improves efficiency, leading to significant operational cost savings.

Better Data Security

ERP systems provide high-end user permission settings, which add extra layers of security to your most sensitive data while making it accessible for the required operations.

Real-time Information

ERP provides real-time information about resource allocation, production levels, inventory status, etc. This allows for immediate response to changing conditions and demands.

Improved Customer Service

A unified and streamlined system allows quicker response times, improved on-time delivery performance, and a better customer experience.

Better Compliance

Manufacturing ERP software provides features like audit trails and reporting capabilities and ensures compliance with industry and government regulations.

15 Best ERP Software for Manufacturing

Here are the top 15 ERP software solutions tailored for the manufacturing industry. These options are designed to optimize production processes, manage resources efficiently, and support business growth.

1. Kohezion

Kohezion offers a user-friendly, customizable online database that empowers manufacturers to create their own ERP solutions without coding. This software stands out for its adaptability and cost-effectiveness, making it a great choice for small to mid-sized businesses.

Top 5 Features:

- Drag and drop application builder

- Comprehensive data management and analysis

- Customizable templates for various business processes

- Robust security with frequent backups

- Integration capabilities with other tools

Benefits:

- No programming skills are required to set up the system

- Scalable solution grows with your business

- Improves collaboration with real-time data access

- Streamlines operations by minimizing manual tasks

- Affordability makes it accessible for smaller operations

Cons:

- May lack some advanced features found in other solutions

- Self-service model requires you to build your own ERP, which may take time

Best For: Small to medium-sized manufacturing businesses looking for a cost-effective, tailored ERP solution that they can develop internally.

2. Epicor Kinetic

Epicor Kinetic provides a deep and comprehensive suite of tools to improve productivity and operational efficiency. Navigating the intricate demands of modern manufacturing becomes smoother with its intuitive cloud-based ERP system, designed to be scalable and industry-specific.

Top 5 Features:

- Advanced Production Management

- Real-time Inventory Management

- Broad Supply Chain Management capabilities

- Role-Based Workbenches and Dashboards

- Extensive Financial Management tools

Benefits:

- Streamlines complex manufacturing processes and workflows

- Supports real-time decision-making with accessible data insights

- Improves supply chain visibility and collaboration

- Adapts to unique business needs with extensive customization options

- Offers industry-specific features for more relevant application

Cons:

- May require a longer learning curve due to its depth of functionality

- Implementation can be more complex compared to simpler platforms

Best For: Mid-sized to larger manufacturing businesses looking for an ERP solution with deep industry-specific capabilities and the flexibility to scale as they grow.

3. Acumatica

Acumatica provides a comprehensive, cloud-based ERP solution tailored specifically for manufacturing. Its prowess lies in integrating core business functions with powerful manufacturing capabilities, making it a compelling choice, especially for small—to mid-sized enterprises looking to maximize efficiency.

Top 5 Features:

- Industry-specific editions for different manufacturing needs

- Comprehensive Order Management module with requisitions and inventory tracking

- Field Service module for on-site operations

- Advanced technology use, including AI, IoT, and augmented reality

- User-friendly interface with global adaptability

Benefits:

- Allows for seamless business operations spanning various departments and functions

- Ensures real-time data is at the fingertips of those who need it

- Scales effectively as business needs grow and change

- Improves customer satisfaction through improved service delivery

- Offers a competitive edge with the latest technological integrations

Cons:

- The extensive features may lead to a steeper learning curve for some users

- Pricing can be perceived as high for smaller businesses with tighter budgets

Best For: Manufacturers, particularly smaller operations, looking for an agile, comprehensive ERP solution with advanced technology and a strong customer service focus.

4. Infor CloudSuite Industrial (Syteline)

Infor CloudSuite Industrial, previously known as SyteLine, is a robust ERP solution tailored to complex manufacturing needs. It houses a plethora of features designed to elevate productivity and efficiency in the discrete manufacturing sector, especially for large enterprises with substantial revenue.

Top 5 Features:

- Advanced Planning and Scheduling (APS)

- Field Service and Product Lifecycle Management

- Quality Control and Quality Management

- Financial Management and Analytics

- Project Management tools

Benefits:

- Offers real-time visibility into every facet of manufacturing operations

- Helps in optimizing the supply chain and reducing inventory costs

- Streamlines quality management processes to ensure product excellence

- Integrates financial data for comprehensive financial oversight and analysis

- Enables complex project management with detailed tracking and cost control

Cons:

- May come with a longer implementation period due to its complexity

- The richness of features could result in a more intensive training requirement for staff

Best For: Larger manufacturing enterprises with revenues over $250 million seeking a comprehensive and highly capable ERP system to manage extensive and intricate manufacturing processes.

5. Oracle ERP Cloud

Oracle ERP Cloud is renowned for its ability to scale and support complex operations, making it a premier choice for large enterprises. Its functionality spans across finance, human resources, and customer experience, all within its full suite of supply chain and manufacturing applications.

Top 5 Features:

- AI-embedded business processes for smarter decision-making

- Real-time analytics and advanced reporting

- Comprehensive supply chain and project management modules

- Robust risk management and compliance features

- Extensive integration with other systems and technologies

Benefits:

- Improves strategic planning with predictive insights and real-time data

- Streamlines operations by automating core business processes

- Ensures regulatory compliance and reduces risk with advanced security features

- Facilitates global transactions with multi-currency and multi-language support

- Empowers the workforce with collaborative and mobile capabilities

Cons:

- Can be cost-prohibitive for small and midsize businesses

- The vast array of features may present a steep learning curve

Best For: Oracle ERP Cloud is best suited for large manufacturing companies seeking a powerful, robust ERP system to handle complex, global operations with sophisticated requirements.

6. Plex Manufacturing Cloud

Plex Manufacturing Cloud is a great choice for manufacturers seeking a comprehensive, cloud-first ERP system. With a strong focus on the manufacturing industry, this platform lends itself to improving operational efficiency, ensuring quality, and driving innovation through its suite of tools.

Top 5 Features:

- Complete Manufacturing Execution System (MES) capabilities

- Intuitive Inventory and Supply Chain Management

- End-to-End Quality Management

- Detailed Plant Floor Control and Monitoring

- Robust Business Intelligence and Analytics tools

Benefits:

- Drill down into every aspect of production for unparalleled operational control

- Improve supply chain transparency, reduce waste, and improve delivery times

- Ensure top-notch quality and compliance with comprehensive quality systems

- Leverage real-time data for smarter decision-making and innovation

- Benefit from the continuity and security offered by cloud-based architecture

Cons:

- Might be overbuilt for smaller manufacturers with less complexity

- Transitioning to a fully cloud-based solution could be challenging for companies with legacy systems

Best For: Mid-sized to large manufacturers embracing cloud technology to streamline their complex operations and who are looking to capitalize on real-time data analytics to improve their processes.

7. Global Shop Solutions

Global Shop Solutions (GSS) offers both cloud and on-premise solutions. It caters to a wide range of industries, which underlines its reputation for reliable and seamless integration of manufacturing operations.

Top 5 Features:

- Unified Global Accounting for consolidated financial management

- Robust Inventory Planning and Automation tools

- Extensive Supply Chain Optimization

- Comprehensive Order Management System

- Integrated Engineering and Production modules

Benefits:

- Integrates multiple facets of business operations for improved efficiency

- Reduces lead times and streamlines inventory management with precision control

- Bolsters the ability to manage complex supply chains

- Provides in-depth insights into financials to help drive profitable decision-making

- Improves customer satisfaction with efficient order processing and management

Cons:

- Setup and customization may require a significant time investment

- The breadth of features could overwhelm smaller operations

Best For: Small—to mid-sized discrete manufacturers searching for a reliable ERP system that can grow with their business.

8. Odoo

Odoo is a highly versatile, open-source ERP platform with a modular structure. It allows manufacturers to start with a simple set-up and add functionalities as needed. The extensive app store lets users improve their system in sync with their evolving business needs.

Top 5 Features:

- Customizable modules for different business operations

- Integrated apps for CRM, Sales, Inventory, and more

- User-friendly Point of Sale (POS) systems

- Real-time communication and collaboration tools

- Strong focus on usability with a straightforward interface

Benefits:

- Enables scalable growth with a la carte module selection

- Fosters productivity with an intuitive, easy-to-navigate user experience

- Allows comprehensive management of operations from a unified interface

- Encourages customer engagement with robust CRM and sales apps

- Supports cost efficiency with open-source access and varied subscription options

Cons:

- The initial free version may require additional customization and apps, leading to increasing costs

- Because of wide-ranging capabilities, some users may need help navigating all available options

Best for: Small—to mid-sized businesses looking for an ERP solution that grows with them and can be tailored to their specific manufacturing and business processes.

9. IFS Applications

IFS Applications offers a unique blend of agility and strength. With IFS Cloud, formerly known as IFS Applications 10.0, businesses get a versatile enterprise system that integrates ERP, EAM, and ESM to streamline core processes like Manufacturing and Supply Chain.

Top 5 Features:

- Modular architecture for easy customization

- Engineering-focused solutions for asset and service-centric operations

- Project lifecycle management for end-to-end project completion

- Mobile workforce empowerment with a suite of field service capabilities

- Robust business intelligence with tailored analytics and reporting

Benefits:

- Delivers industry-specific functionality tailored for large and mid-sized organizations

- Supports complex, global operations with multi-language and multi-currency capabilities

- Facilitates superior use management and optimization of physical assets

- Improves customer service with comprehensive enterprise service management

- Offers flexible deployment options, including cloud and on-premise solutions

Cons:

- May require a significant amount of training for full software utilization

- The range of features and adaptability might be more than needed for smaller enterprises

Best For: Manufacturers, particularly those with heavy assets or service-centric models, looking for a customizable and comprehensive solution that can handle sophisticated global operations.

10. Sage Business Cloud X3

Sage Business Cloud X3, also known as Sage X3, is tailored to empower businesses to manage their enterprise operations with greater speed, efficiency, and flexibility. It's an ERP solution designed to drive business growth by consolidating various functionalities, including sales, finance, and production into one cohesive system.

Top 5 Features:

- Advanced and flexible financial management

- Integrated business intelligence tools

- Comprehensive supply chain and production management

- Real-time analytics and insights

- End-to-end CRM solution

Benefits:

- Unifies critical business processes for seamless operation

- Provides actionable insights leading to data-driven decisions

- Optimizes supply chain operations, reducing costs and improving margins

- Improves CRM with detailed tracking and customer insight tools

- Quick adaptation to regulatory changes through its agile framework

Cons:

- Small businesses may find its broad scope more than they require

- Customizations might necessitate additional time and resources to align with unique workflows

Best For: Sage Business Cloud X3 is particularly well-suited for medium—and large-sized manufacturers who require robust ERP capabilities and want to gain a competitive advantage through integrated and intelligent systems.

11. QAD Adaptive ERP

QAD Adaptive ERP champions the cause of agile and adaptive manufacturing processes by focusing on the automotive, consumer products, and life sciences industries. Providing real-time insights and a fully integrated suite facilitates the rapid response required in the constantly changing manufacturing sector.

Top 5 Features:

- Industry-Specific Focus for targeted functionality

- Adaptive User Experience for personalized workflows

- Advanced Analytics and Reporting for actionable insights

- Effective Demand and Supply Chain Management tools

- Cloud-based flexibility and scalability

Benefits:

- Delivers deep industry functionality to meet specific operational needs

- Improves user productivity with an adaptable and intuitive interface

- Supports informed decision-making through comprehensive analytics

- Optimizes the supply chain for decreased costs and improved performance

- Offers a flexible cloud platform that scales with your business needs

Cons:

- May have a longer deployment period for full-scale customization

- Some businesses may find the industry-specific tools more complex than necessary

Best For: Large manufacturers, especially in highly regulated industries, that need a robust ERP system to facilitate growth and agile adaptation to industry disruptions.

12. Deacom ERP

Deacom ERP provides comprehensive solutions for process and batch manufacturers. With its unique approach to tackling the complex needs of businesses in the food, beverage, chemical, and pharmaceutical sectors, Deacom ERP stands out for its all-encompassing, natively integrated ERP capabilities.

Top 5 Features:

- In-depth Process Control for consistent quality

- Advanced Formulation and Inventory Management

- Direct Store Delivery (DSD) and Warehouse Management System (WMS)

- Regulatory compliance and reporting tools

- Centralized business operations platform

Benefits:

- Helps ensure product quality and consistency with robust process controls

- Streamlines inventory and warehouse management for efficiency and cost control

- Facilitates compliance with industry regulations and standards

- Consolidates business operations into a single, cohesive system

- Reduces IT complexity by eliminating the need for multiple software solutions

Cons:

- May require a period of adjustment for users familiar with traditional ERP systems

- The specialized focus might not suit all manufacturing verticals

Best For: Manufacturers in process industries such as food and beverage, chemicals, or pharmaceuticals who demand an ERP solution with strong regulatory compliance and real-time data management capabilities.

13. SYSPRO

SYSPRO is acclaimed for its ability to handle the nuances of manufacturing and distribution with precision and flexibility. Offering a deep well of ERP capabilities, SYSPRO caters particularly to businesses navigating the complex operational challenges of these sectors, focusing on helping companies streamline their processes and maximize profitability.

Top 5 Features:

- Tailored ERP solutions for manufacturers and distributors

- Advanced Production Scheduling and Management tools

- Comprehensive Order Management and Inventory Management systems

- Real-time Insights with Integrated Business Intelligence

- Connectivity with IoT, AI, and other emerging technologies

Benefits:

- Improves operational efficiency with industry-specific features

- Delivers real-time data for informed decision-making and quick reaction to market changes

- Provides traceability and compliance for regulatory requirements

- Aids strategic business growth with scalable cloud or on-premises deployment options

- Boasts a high customer satisfaction and retention rate, with over 90% of SYSPRO users satisfied three years into the use

Cons:

- The specialization in manufacturing and distribution may make it less suitable for other business models

- High customization capabilities might require more planning and longer implementation times

Best For: Mid-sized to large companies in the manufacturing and distribution space looking for a robust ERP solution with a proven track record of customer satisfaction and the flexibility of cloud or on-premises deployment.

14. Fishbowl

Fishbowl brings an inventory-centric approach to ERP solutions, making it an attractive option for small to midsize businesses. With its focus on warehouse and manufacturing management, Fishbold excels as a stand-alone inventory management system or as an add-on to existing accounting solutions like QuickBooks.

Top 5 Features:

- Advanced Inventory Management with real-time updating

- Manufacturing Order Management and tracking

- Integration with QuickBooks for seamless accounting

- Order Management with support for multiple locations

- Materials Requirements Planning (MRP) for efficient resource utilization

Benefits:

- Elevates inventory accuracy with detailed tracking and reporting

- Streamlines manufacturing workflows with centralized order management

- Seamlessly connects to QuickBooks, avoiding duplicate data entry

- Improves efficiency with comprehensive order fulfillment processes

- Provides crucial foresight into material needs to maintain optimal production levels

Cons:

- May not scale as efficiently for larger enterprises with more complex needs

- Focuses primarily on inventory and manufacturing operations, potentially requiring additional software for full ERP functionality

Best For: Small to midsize manufacturers focused on inventory management and those already using QuickBooks who are looking to integrate with a more robust manufacturing and stock system.

15. Deltek Costpoint

Deltek Costpoint is revered among businesses that deal with government contracts due to its sophisticated project accounting, labor management, and billing features. Its expertise in managing complex project requirements makes it a favorite for aerospace, defense, and other project-based manufacturers.

Top 5 Features:

- Project Accounting and Revenue Recognition

- Contract Management and Compliance

- Labor Management and Human Capital Management

- Supply Chain Management and Procurement

- Business Intelligence and Reporting

Benefits:

- Enables precise tracking and management of project finances

- Facilitates government contracting compliance with robust audit trails and reports

- Integrates labor management to optimize workforce productivity

- Manages complex supply chains with a comprehensive procurement module

- Delivers actionable insights with advanced business intelligence tools

Cons:

- The specialized emphasis on project-based processes may be more than what some businesses need

- Can be on the upper end of the price spectrum for smaller businesses

Best For: Manufacturers that engage significantly in government contracting and require a sophisticated ERP system to handle the intricacies of project-based manufacturing, from accounting to compliance.

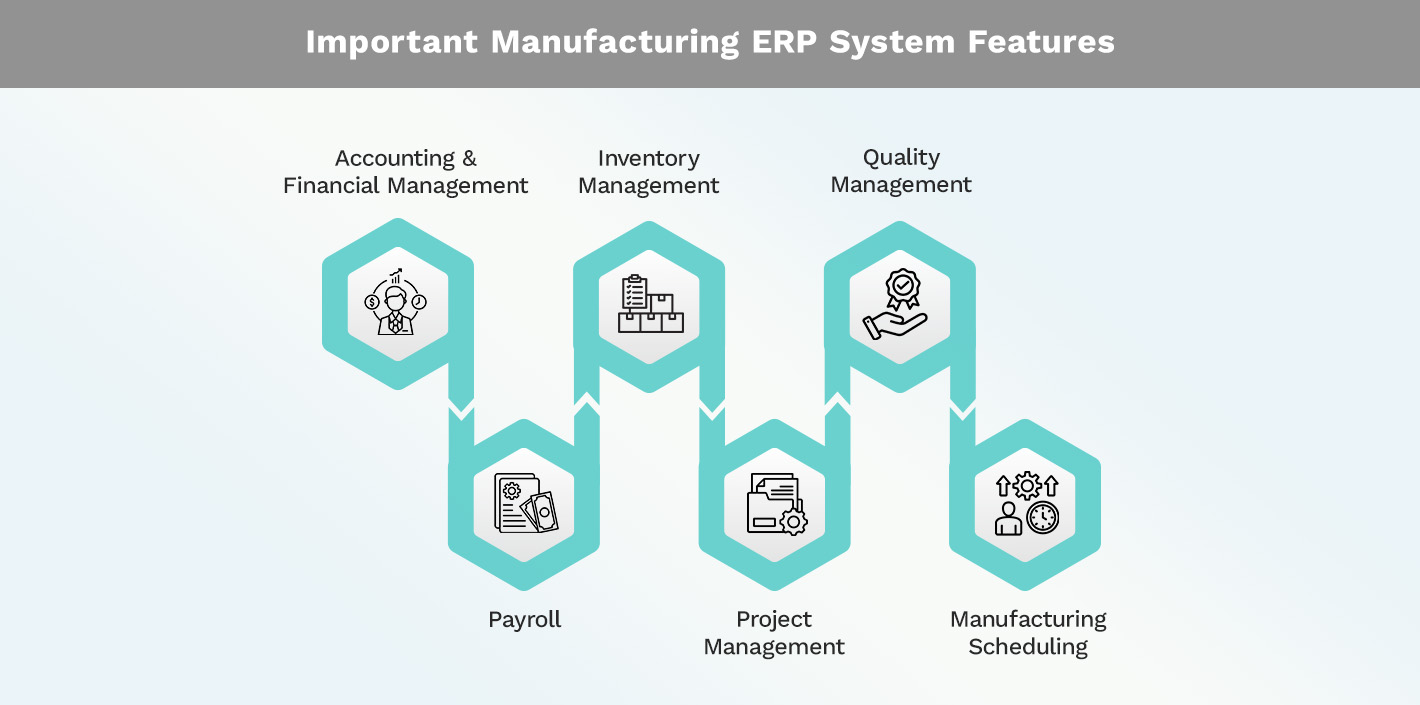

Important Manufacturing ERP System Features

To effectively manage your manufacturing operations, ensure your ERP system includes these vital features:

Accounting & Financial Management

ERP systems simplify the process of keeping accurate accounting records. They can automatically track and sync accounts payable and receivable and manage tax bookkeeping, reducing the risk of human error.

Payroll

This function ensures that payroll is always properly authorized and disbursed. Automated payroll functions track overtime and ensure timely payment for your workforce.

Inventory Management

Inventory management improves visibility into inventory levels in real time. It facilitates tracking the movement of raw materials, work in progress, and finished goods, streamlining procurement and sales processes.

Project Management

ERP software often comes equipped with project management features, enabling effective planning and tracking of production, materials, and costs.

Quality Management

ERP software tracks manufacturing processes, manages tests and inspections, and adheres to international quality standards, which aids businesses in maintaining product quality.

Manufacturing Scheduling

ERP systems can manage a master production schedule, offering insights into production timelines, resource allocation, and capacity planning.

Build an Effective Manufacturing ERP with Kohezion

An effective manufacturing ERP system streamlines your manufacturing processes, improves productivity, and drives business growth. Kohezion stands out for its high customizability, ease of use, and robust capabilities. It allows users to build their applications without any need for coding, making it one of the most user-friendly ERP solutions for manufacturing businesses.

However, the right ERP for your company depends largely on your unique business needs and constraints. Before making your final decision, be sure to consider factors such as scalability, integration, user-friendliness, industry-specific features, costs, and vendor support.

Conclusion

Selecting the right ERP system for your manufacturing operations is a critical decision that can significantly impact your business's health and growth. Whether you choose Kohezion for its simplicity and customization, Epicor Kinetic for its depth, Acumatica for advanced technological integration, or another system from our list of the 15 best ERP solutions, each has distinct features and benefits tailored to various business needs and sizes.

Implementing an ERP system is an investment in software and the future efficiency and success of your manufacturing processes. Contact us today for more information or to see how Kohezion can support your manufacturing business.

Frequently Asked Questions

The cost to implement an ERP system for manufacturing varies widely, depending on factors such as the size of your business, the scope of your processes, and the specific ERP solution you choose. It can range from zero for open-source options to millions of dollars for complete, customized solutions.

Typically, costs include software licensing, implementation fees, ongoing support, and other necessary hardware, network, and personnel expenses. Each company must carefully assess these elements to estimate the investment required for ERP implementation. However, while initial costs are important, the focus should be on the system's value over its lifecycle.

Cloud-based ERP differs from on-premise ERP in its delivery model and operational approach. Cloud ERP is hosted on the vendor's servers and accessed via the internet, offering quick deployment, lower upfront costs, and simplicity in system maintenance as the vendor handles updates and security.

On-premise ERP, however, is installed locally on your company's hardware and servers, granting you full control over the system and data, but with higher initial costs and a need for an in-house IT team to manage and maintain the software. Both have their own advantages, so manufacturers must consider their specific needs, resources, and strategic goals when choosing between them.

Manufacturing ERP software supports regulatory compliance by automating the tracking, management, and documentation of compliance-related activities. It ensures that processes adhere to industry standards and legal requirements by maintaining accurate records, managing quality control, and providing detailed audit trails.

An ERP system can also update compliance measures as regulations change, reducing the risk of non-compliance penalties and helping maintain a clear status on compliance across the organization. This way, manufacturers can focus on production, confident that their ERP system is assisting in the complex task of compliance management.

AI and machine learning in manufacturing ERP systems lead to smarter, more autonomous operations. They can significantly improve decision-making by analyzing vast datasets to uncover insights and patterns, which can predict maintenance needs, optimize supply chains, and improve product quality.

AI-driven automation can handle routine tasks, freeing up human workers for more complex, value-added activities. The result is increased efficiency, reduced human error, and the ability to rapidly respond to changing market demands. Manufacturers can evolve towards Industry 4.0 with AI and machine learning, embracing more interconnected and intelligent systems.

Measuring the ROI of an ERP system in manufacturing involves assessing both quantitative and qualitative benefits against the investment made. Evaluate metrics such as reduced operational costs, increased productivity, and improved inventory turnover. Also, consider factors like improved decision-making, better compliance, or improved customer satisfaction. A successful ERP system should lead to streamlined operations and increased profitability, demonstrating a positive return on investment.