Recent studies reveal that 45% of chemical enterprises are investing in digital solutions like ERP systems to improve efficiency and compliance. These solutions help manage production, follow rules, and mix chemicals well.

In this guide, we compare the top 10 chemical ERP solutions for 2024, detailing their key features, benefits, and limitations. This comparison will help you make an informed decision, whether you aim to improve production management or streamline compliance processes.

What is Chemical ERP Software

Chemical ERP software is a type of enterprise resource planning software made for the chemical industry. It helps manage and improve business processes for making, distributing, and following rules for chemical products. To understand Chemical ERP, we need to see how it's different from regular ERP solutions. It has special features that meet the chemical industry's unique needs.

Chemical ERP combines different tasks like managing formulas and tracking rules. For instance, BatchMaster Software is great at managing formulas and following GHS rules, which are key for staying in line and working efficiently in chemical making.

This software gives companies better control over their work, from getting raw materials to sending out products. Chemical makers get to see more and make better choices. This helps them work better and make more money.

Why is Chemical ERP Software Important

Chemical ERP software helps solve the unique problems of the chemical industry. It helps with complex supply chains, strict rules, and the need for quick product updates. A good ERP system helps you handle these issues well.

Having real-time data helps make better decisions. It also keeps your business in line with laws at home and abroad, significantly lowering the chance of breaking the law, which is a big worry in the chemical world.

ERP systems do more than just follow the rules. They make your operations more flexible, letting you change and grow with market changes.

Chemical ERP software helps you tackle problems and sets your business up for long-term growth. Managing resources well and analyzing trends increase productivity and innovation.

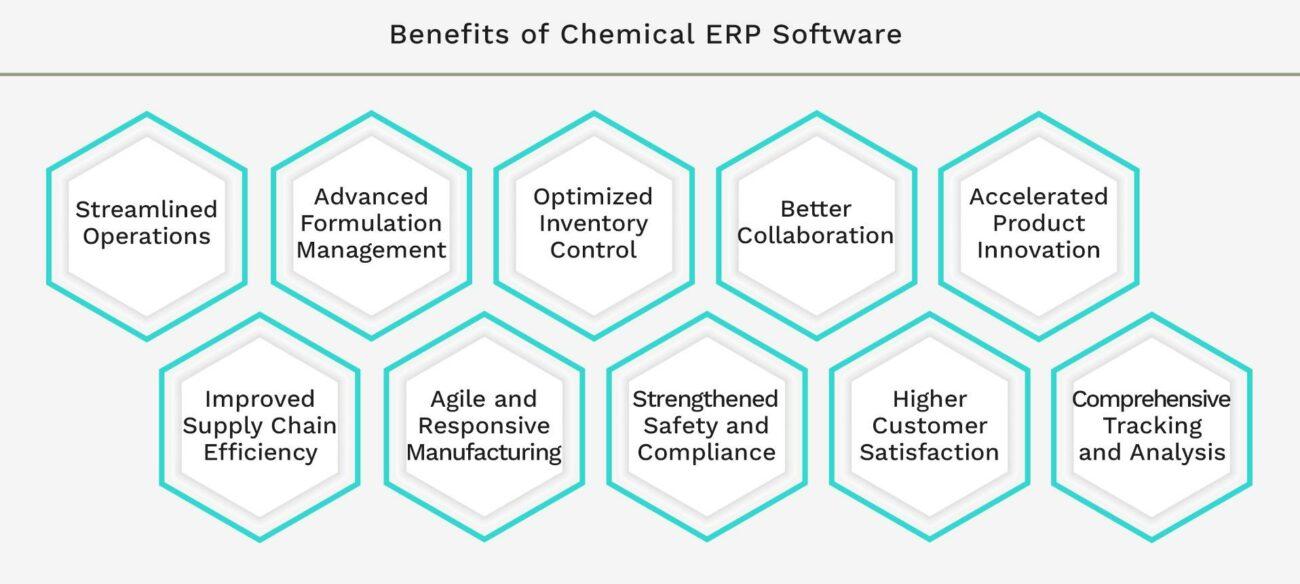

Benefits of Chemical ERP Software

Chemical ERP software brings many benefits to your business in the chemical industry. It increases productivity, efficiency, and performance. These benefits help streamline operations and support product innovation in chemicals.

Streamlined Operations

Streamlining operations reduces cycle times, which means quicker responses and better efficiency. It also reduces downtime and makes the best use of resources.

Advanced Formulation Management

Advanced formulation management gives you control over recipes and formulations, ensuring quality consistency in your products. It meets the high standards of the chemical sector.

Optimized Inventory Control

Optimizing inventory control reduces waste from too much stock and ensures the right products are available when needed, leading to cost savings and better operational efficiency.

Better Collaboration

Good teamwork leads to better communication and project coordination. Strong teams solve problems faster and meet project deadlines, helping achieve goals smoothly.

Accelerated Product Innovation

Chemical ERP software helps speed up product innovation. It improves communication and resource management, allowing your organization to quickly meet market demands and bring new products to market ahead of competitors.

Improved Supply Chain Efficiency

An improved supply chain increases operational efficiency and reduces risks from delays or disruptions, helping you keep products available and meet customer needs.

Agile and Responsive Manufacturing

Being agile in manufacturing allows you to quickly change production schedules and processes. This flexibility helps your business quickly adapt to demand changes or operational issues.

Strengthened Safety and Compliance

Improving safety and compliance ensures your operations follow industry rules and standards. This focus on compliance shields your business from legal issues and improves your reputation with customers.

Higher Customer Satisfaction

With better operational efficiency and product quality, customers are happier. Happy customers stay loyal and recommend your products to others.

Comprehensive Tracking and Analysis

Deep data tracking and analysis provide valuable insights for making decisions. This information helps spot trends that guide future strategies, making your business more effective.

Top 10 Chemical ERP Software Solutions

To help you navigate the complex landscape of ERP systems, here’s a list of the top 10 chemical ERP software solutions for 2024. Each option is evaluated based on its features, benefits, and suitability for the chemical industry.

1. Kohezion

Kohezion offers a flexible ERP solution tailored for the chemical industry, emphasizing customization and ease of use. It supports essential chemical manufacturing processes and regulatory compliance needs. Its user-friendly interface allows for seamless integration with existing systems.

Top 5 Features:

- Customizable Dashboards: Tailor data views to specific needs.

- Regulatory Compliance Tools: Manage industry regulations effectively.

- Batch Tracking: Monitor production batches in real-time.

- Inventory Management: Optimize stock levels and reduce waste.

- Formulation Management: Control and adjust product formulations.

Benefits:

- Flexible Customization: Adapt the software to fit unique business needs.

- Ease of Use: Intuitive interface simplifies training and usage.

- Regulatory Compliance: Helps meet industry standards and regulations.

- Improved Efficiency: Streamlines operations and reduces errors.

- Real-Time Insights: Provides up-to-date information for better decision-making.

Cons:

- Limited Advanced Features: May lack some complex functionalities.

- Scaling Challenges: May face difficulties with larger operations.

Best For: Small to medium-sized chemical companies looking for a customizable and user-friendly ERP solution.

2. Absolute ERP

Absolute ERP is designed to meet the needs of the chemical industry with robust functionality for production and compliance. It offers comprehensive tools for managing inventory, production, and regulatory requirements. Its modular approach allows businesses to scale the system as needed.

Top 5 Features:

- Comprehensive Inventory Management: Track and manage inventory accurately.

- Production Scheduling: Plan and optimize manufacturing processes.

- Regulatory Compliance: Ensure adherence to industry regulations.

- Quality Control: Monitor and maintain product quality.

- Modular Design: Add or remove features as needed.

Benefits:

- Versatile Functionality: Supports a wide range of chemical processes.

- Scalable System: Adjust the system to match business growth.

- Improved Compliance: Meets regulatory requirements effectively.

- Improved Production Planning: Streamlines manufacturing operations.

- Quality Assurance: Maintains high product standards.

Cons:

- Complex Implementation: May require extensive setup and training.

- Higher Cost: Can be more expensive compared to other solutions.

Best For: Medium to large chemical companies needing a scalable and comprehensive ERP solution.

3. SAP Business One

SAP Business One is an ERP solution for small and mid-sized chemical companies. It integrates various business functions into a single platform, offering finance, production, and inventory management features. The system provides advanced analytics and real-time reporting capabilities.

Top 5 Features:

- Integrated Financial Management: Manage finances seamlessly.

- Production Management: Oversee and optimize production processes.

- Inventory Control: Track and manage stock levels effectively.

- Real-Time Reporting: Access up-to-date business insights.

- Advanced Analytics: Analyze data for better decision-making.

Benefits:

- Comprehensive Integration: Unifies various business processes.

- Improved Reporting: Provides valuable insights into operations.

- Improved Production Efficiency: Optimizes manufacturing workflows.

- Financial Management: Handles accounting and financial tasks.

- Scalable Solution: Grows with your business needs.

Cons:

- Complex Setup: Can be challenging to implement.

- High Cost: May be pricey for smaller businesses.

Best For: Small to mid-sized chemical companies seeking an integrated and analytics-driven ERP solution.

4. Oracle NetSuite

Oracle NetSuite offers a cloud-based ERP solution for chemical companies. It provides tools for financial management, inventory control, and production planning. Its comprehensive suite of applications helps businesses streamline operations and improve efficiency. NetSuite’s scalability makes it suitable for growing companies.

Top 5 Features:

- Cloud-Based Access: Access the system from anywhere.

- Financial Management: Handle accounting and financial tasks.

- Inventory and Order Management: Track and manage stock and orders.

- Production Planning: Plan and optimize manufacturing processes.

- Scalability: Adapt the system to business growth.

Benefits:

- Cloud Accessibility: Use the software from any location.

- Streamlined Operations: Integrates various business functions.

- Improved Efficiency: Improves business processes.

- Scalable: Suitable for growing companies.

- Advanced Reporting: Provides detailed business insights.

Cons:

- High Cost: Can be expensive for some businesses.

- Complex Implementation: May require significant setup and training.

Best For: Mid to large chemical companies needing a robust and scalable cloud-based ERP solution.

5. Epicor ERP

Epicor ERP provides a flexible solution for the chemical industry. Its features are designed to support complex manufacturing processes and regulatory requirements. Its modular system allows for customization to fit specific business needs. Epicor focuses on improving operational efficiency and product quality.

Top 5 Features:

- Modular System: Customize the ERP to fit specific needs.

- Production Management: Optimize manufacturing workflows.

- Regulatory Compliance: Ensure adherence to industry regulations.

- Quality Control: Monitor and maintain product quality.

- Inventory Management: Track and manage stock levels.

Benefits:

- Flexible Customization: Tailor the system to business needs.

- Improved Efficiency: Streamlines manufacturing and operations.

- Regulatory Support: Meets industry compliance requirements.

- Improved Quality: Maintains high standards for products.

- Scalable Solution: Grows with your business.

Cons:

- Complex Setup: Implementation can be challenging.

- Higher Cost: More expensive than some alternatives.

Best For: Chemical companies needing a customizable and efficient ERP solution.

6. AlignBooks

AlignBooks offers an ERP solution for the chemical industry that focuses on simplicity and ease of use. It provides tools for financial management, inventory control, and production planning. The system is designed to be user-friendly and cost-effective for small—to medium-sized businesses.

Top 5 Features:

- Financial Management: Handle accounting and financial tasks.

- Inventory Control: Manage stock levels efficiently.

- Production Planning: Optimize manufacturing processes.

- User-Friendly Interface: Simplifies software usage.

- Cost-Effective: Affordable for smaller businesses.

Benefits:

- Ease of Use: Intuitive interface simplifies operations.

- Cost Savings: Budget-friendly solution.

- Efficient Inventory Management: Tracks stock levels accurately.

- Streamlined Production: Improves manufacturing processes.

- Integrated Financials: Manages financial tasks effectively.

Cons:

- Limited Advanced Features: May lack some complex functionalities.

- Scalability Issues: Less suitable for larger operations.

Best For: Small to medium-sized chemical companies looking for an affordable, user-friendly ERP solution.

7. Acumatica

Acumatica is a cloud-based ERP solution for chemical companies. It offers comprehensive tools for financial management, inventory control, and production planning. The system's flexible and scalable design supports various business needs and growth. It also provides robust reporting and analytics capabilities.

Top 5 Features:

- Cloud-Based Access: Use the software from anywhere.

- Financial Management: Handle financial operations efficiently.

- Inventory Control: Manage and track stock levels.

- Production Planning: Optimize manufacturing workflows.

- Advanced Reporting: Access detailed business insights.

Benefits:

- Flexible and Scalable: Adapts to business growth and needs.

- Cloud Accessibility: Access the system remotely.

- Improved Efficiency: Streamlines various business processes.

- Improved Reporting: Provides valuable insights.

- Comprehensive Features: Supports multiple business functions.

Cons:

- High Cost: May be expensive for smaller companies.

- Complex Setup: Implementation can be challenging.

Best For: Growing chemical companies needing a flexible and cloud-based ERP solution.

8. Odoo

Odoo offers a modular ERP solution for the chemical industry, with a range of applications for managing finance, inventory, and production. Its open-source platform allows for customization and integration with other systems. Odoo is known for its user-friendly design and affordability.

Top 5 Features:

- Modular System: Customize with various applications.

- Inventory Management: Track and manage stock efficiently.

- Production Management: Optimize manufacturing processes.

- Financial Management: Handle accounting tasks effectively.

- User-Friendly Interface: Easy to navigate and use.

Benefits:

- Customizable Modules: Adapt the system to specific needs.

- Cost-Effective: Affordable compared to other ERP solutions.

- Ease of Use: Intuitive and user-friendly design.

- Integration Capabilities: Connects with other systems easily.

- Scalable: Suitable for growing businesses.

Cons:

- Limited Advanced Features: May lack some complex functionalities.

- Implementation Complexity: May require technical expertise.

Best For: Small to mid-sized chemical companies seeking a customizable and affordable ERP solution.

9. SYSPRO ERP

SYSPRO ERP provides a comprehensive solution for the chemical industry, with features designed to support manufacturing, inventory, and regulatory compliance. Its scalable system can be tailored to meet specific business requirements. SYSPRO focuses on improving operational efficiency and product quality.

Benefits:

- Improved Operational Efficiency: Streamlines various business functions.

- Customizable Solution: Tailor the system to specific needs.

- Regulatory Support: Meets industry compliance requirements.

- Improved Quality Control: Maintains product standards.

- Scalable System: Grows with your business.

Cons:

- Complex Implementation: May require significant setup and training.

- Higher Cost: Can be more expensive than some alternatives.

Best For: Medium to large chemical companies needing a comprehensive and scalable ERP solution.

10. Tally.ERP 9

Tally.ERP 9 is an ERP solution known for its simplicity and affordability. It is suitable for small—to medium-sized chemical businesses and offers core functionalities for financial management, inventory control, and production planning. Tally.ERP 9 is designed to be user-friendly and easily implementable.

Top 5 Features:

- Financial Management: Manage accounting and financial tasks.

- Inventory Management: Track and control stock levels.

- Production Planning: Optimize manufacturing processes.

- User-Friendly Interface: Simple and easy to use.

- Affordable Pricing: Cost-effective for smaller businesses.

Benefits:

- Ease of Use: Intuitive design simplifies operations.

- Cost-Effective: Budget-friendly solution.

- Efficient Inventory Management: Accurately tracks stock levels.

- Streamlined Financials: Manages accounting tasks effectively.

- Simple Implementation: Easy to set up and use.

Cons:

- Limited Advanced Features: May lack complex functionalities.

- Scalability Issues: Less suitable for larger operations.

Best For: Small to medium-sized chemical companies seeking an affordable, easy-to-use ERP solution.

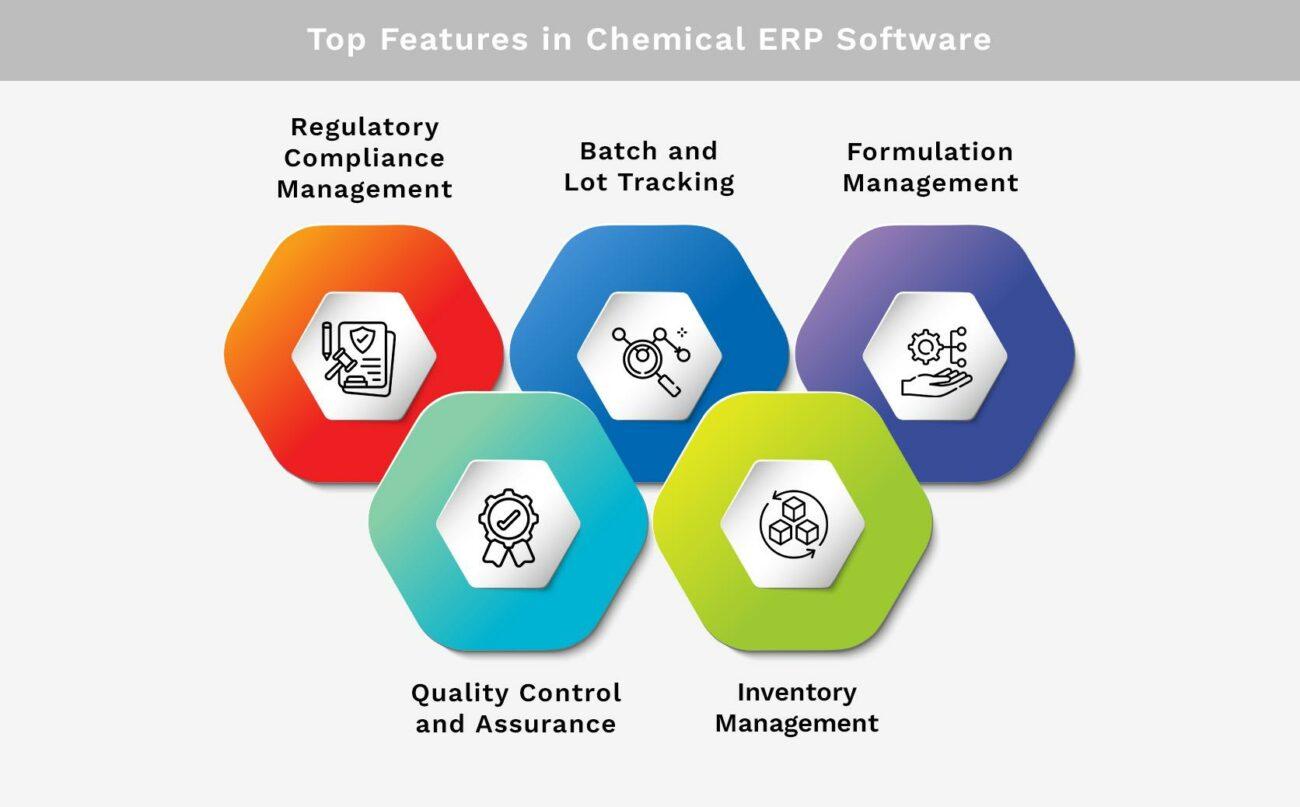

Top Features in Chemical ERP Software

Chemical ERP software has key features that can greatly improve your operations and meet industry standards. These features help with managing resources and following regulations. Here are some important features to look for in a chemical ERP solution.

Regulatory Compliance Management

These tools help your business stay compliant with complex regulations like GHS and REACH, reduce the chance of fines, and support green practices.

Batch and Lot Tracking

Tracking batches and lots is vital for quality and recall management. It lets you keep an eye on products from start to finish. This ensures you can trace and account for every product, keeping your business in line with regulations.

Formulation Management

Managing formulations helps control production recipes accurately. This reduces mistakes and keeps product quality consistent. It also makes updating recipes as needed to meet customer demands easier.

Quality Control and Assurance

Quality control systems prevent mistakes and ensure products meet standards. This feature's regular checks and reports increase your operation’s reliability and trust.

Inventory Management

Good inventory management helps you use resources wisely, avoid stockouts, and reduce excess. This feature helps you adapt quickly to market changes while keeping costs down.

What is the Cost of Chemical ERP Software?

The cost of chemical ERP software varies widely. It depends on the provider and the features you choose. On average, costs range from $30,000 to $1,000,000.

Many factors affect the price. These include the number of users you have, the complexity of the features, and whether you need custom changes. When planning your budget for chemical software, you'll need to consider initial licensing fees. Implementation costs start at around $15,000 and can go up depending on the size of your deployment.

Don’t forget ongoing maintenance costs, which add up over time. Consider your budget for both the start and the long run. To get the best deal, get quotes from different providers. This way, you can find a solution that fits your needs and budget.

How to Choose the Best Chemical ERP Software?

Choosing the right chemical ERP software helps streamline operations and increases productivity. Here are steps to guide you in making the best choice.

Identify Your Business Needs

First, understand your business needs. Examine your current processes, challenges, and goals to ensure the software meets your unique needs.

Evaluate Software Compatibility

Next, check if the software fits with your current systems. Choosing software that works well with your tools reduces disruption and makes implementation smoother.

Check for Industry-Specific Features

Make sure the software has what you need, like handling regulations and managing formulas. This makes it more relevant and easier to use.

Consider Scalability and Flexibility

Your ERP needs may change as your business grows, so look for software that can grow with you.

Request Demos and Customer Reviews

Asking for demos is a smart move. They let you see the software in action, and reading reviews helps you understand how users feel about the software you're looking at.

Explore Kohezion as Your Chemical ERP Solution

Kohezion is a top choice for a chemical ERP system designed for the chemical industry's needs. It offers a flexible and easy-to-use platform. This lets you handle compliance and regulations well.

Kohezion brings big advantages, especially in tracking and managing compliance. Companies using Kohezion for ERP will see better visibility in all processes, from making products to managing stock. This leads to smarter decisions and more efficient operations. Plus, you can tailor the software to fit your business's specific needs.

Conclusion

Choosing the right ERP software is crucial for optimizing operations and ensuring compliance in the chemical industry. By comparing these top 10 solutions for 2024, you can identify the best fit for your business needs and improve efficiency. Each software offers unique features and benefits, so consider your specific requirements and growth plans when making a decision.

For a tailored ERP solution that adapts to your needs, contact us at Kohezion to learn more about how we can support your business.

Start building with a free account

Frequently Asked Questions

Chemical ERP software can help companies track and reduce waste, manage energy use, and optimize resource consumption. Providing detailed data on production processes enables businesses to implement more sustainable practices that benefit the environment and reduce costs.

Yes, most Chemical ERP solutions are designed to integrate with other business systems like CRM, accounting, and supply chain management tools. Integration helps create a seamless flow of information across departments, reducing manual data entry and the risk of errors. This improves business operations and decision-making.

Mobile access lets field agents and business leaders make smart decisions from anywhere. It supports real-time customer interactions, improves negotiation skills, and enables quick actions, leading to stronger customer relationships and better service quality.