In 2022, the global electronics manufacturing services market was valued at $484 billion and is expected to reach $902 billion by 2032. This shows how big and important this industry is. Choosing the right ERP system will make your operations smoother and help your business grow.

The best ERP systems for 2024 are made to fit your business's specific needs. They bring together important functions to improve how well your business runs. We'll look at the top ERP solutions for electronics manufacturing. We'll cover their features, costs, and how they can grow with your business to help you make a smart choice.

What is ERP for Electronics Manufacturing

ERP stands for Enterprise Resource Planning. It's a type of software that helps manage and automate business processes. Electronics manufacturing ERP focuses on production, inventory, and supply chain management in the electronics industry.

ERP systems help businesses run better. They combine financial management, production planning, human resources, and data analytics, making it easier for departments to work together and make smart decisions quickly. ERP systems also help companies get products to market faster and work more efficiently.

An ERP solution for electronics manufacturing gives you a clear view of your production process. You can track parts, manage suppliers, and follow industry rules. ERP helps your business work better and cheaper without losing quality.

Why is ERP for Electronics Manufacturing Important

The world of electronics manufacturing is always changing, bringing new challenges. ERP systems are key to tackling these issues. They help manage the complexity, fast tech changes, and strict rules you face. ERP systems make things run smoother, helping you work better with your team.

ERP systems are great at managing resources well. They make data more accurate, improve workflow, and give you a clear view of your supply chain. They tie together things like planning, keeping track of stock, helping customers, and making your operations work as one unit.

Having ERP ensures you follow industry rules and standards. It helps you keep up with and even beat these rules. With up-to-the-minute data, you can make smart choices that increase your work and profits.

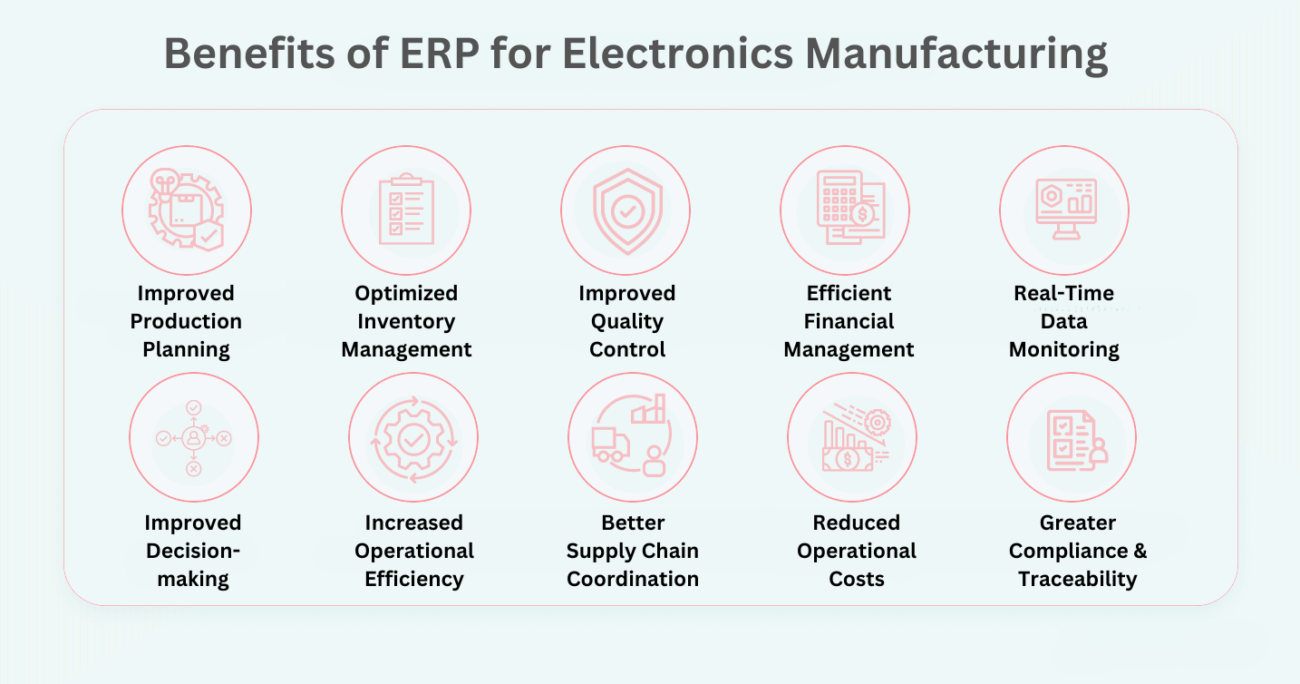

Benefits of ERP for Electronics Manufacturing

An ERP system brings many advantages to the electronics manufacturing industry. Knowing these ERP benefits helps make better decisions in production planning, inventory management, quality control, and financial management.

Improved Production Planning and Scheduling

ERP improves optimizes resource use, which results in production planning and scheduling. This means you can use materials and people more effectively. It helps meet deadlines and keeps production lines running smoothly.

Optimized Inventory Management

ERP makes inventory management more efficient. It reduces holding costs and prevents stockouts. This ensures you have the right stock levels, saving resources and avoiding overstocking.

Improved Quality Control

ERP systems have strong quality control modules. They streamline quality checks during manufacturing. This proactive approach reduces defects, ensuring only high-quality products are sent to customers. It improves your brand's reputation.

Efficient Financial Management

A well-set-up ERP offers accurate financial data and tools. This helps with better budgeting and finding profit margins. It also helps cut costs, increasing profitability.

Real-Time Data Monitoring

ERP systems give you real-time data access, which is a big plus. You can see key performance indicators right away. This lets you make quick changes in production or inventory, helping you stay agile and responsive to market needs.

Improved Decision-Making

ERP systems provide integrated data and analytics for better decision-making. They offer insights that help you make strategic choices about resource use, production, and market trends.

Increased Operational Efficiency

ERP automates routine tasks and streamlines workflows, increasing operational efficiency. It also integrates different departments, leading to smoother operations and less manual work.

Better Supply Chain Coordination

ERP helps with supply chain coordination, keeping suppliers and logistics partners in sync. Managing relationships better ensures timely deliveries and shorter lead times.

Reduced Operational Costs

ERP optimizes various manufacturing aspects, like inventory and labor. This reduces operational costs and allows your business to invest in growth areas, giving you a competitive edge.

Greater Compliance and Traceability

ERP systems keep detailed records and documents. This traceability makes audits easier and ensures you meet safety and quality standards.

10 Best ERPs for Electronics Manufacturing

Choosing the right ERP system helps electronics manufacturers streamline their operations and stay competitive. Here are the 10 best ERPs designed specifically for the electronics manufacturing industry.

1. Kohezion

Kohezion is a highly customizable online database platform that offers powerful solutions tailored to the needs of electronics manufacturers. Its user-friendly interface allows companies to build and manage their own ERP systems without requiring extensive technical knowledge. With features that support inventory tracking, production management, and quality control, Kohezion enables businesses to streamline operations and improve efficiency.

Top 5 Features:

- Customizable database design

- Real-time inventory tracking

- Production management tools

- Automated workflow processes

- Data analytics and reporting

5 Benefits:

- Increased flexibility with customizable features

- Improved visibility into inventory and production

- Improved process automation and efficiency

- Better decision-making with real-time data

- Scalable solutions that grow with your business

2 Cons:

- Limited out-of-the-box integrations

- Requires initial setup time to configure

Best For:

Large electronics manufacturers seeking a customizable, user-friendly ERP solution.

2. Infor CloudSuite

Infor CloudSuite is a comprehensive cloud-based ERP solution designed specifically for the manufacturing industry. It offers end-to-end capabilities, from supply chain management to financials, all within a single platform. Infor CloudSuite’s advanced analytics and AI-driven insights empower manufacturers to optimize operations, reduce costs, and increase profitability.

Top 5 Features:

- Advanced supply chain management

- AI-driven predictive analytics

- Integrated financial management

- Real-time production monitoring

- Cloud-based platform with mobile access

5 Benefits:

- Improved supply chain visibility and control

- Improved decision-making with AI insights

- Streamlined financial processes and reporting

- Increased operational efficiency with real-time data

- Accessible from anywhere with cloud and mobile access

2 Cons:

- Can be costly for smaller businesses

- Complex implementation process

Best For:

Large electronics manufacturers needing a robust, comprehensive ERP solution with advanced analytics.

3. SAP Business One

SAP Business One is an affordable, easy-to-use ERP solution tailored for small to mid-sized businesses, including electronics manufacturers. It integrates all core business functions, such as sales, inventory, production, and financials, into a single platform. SAP Business One helps manufacturers streamline processes, gain better visibility into operations, and make data-driven decisions.

Top 5 Features:

- Integrated financial management

- Inventory and production planning

- Customer relationship management (CRM)

- Real-time business intelligence and reporting

- Mobile access to business data

5 Benefits:

- Unified platform for all core business processes

- Improved inventory and production control

- Better customer management with integrated CRM

- Improved decision-making with real-time insights

- Accessible on-the-go with mobile features

2 Cons:

- Limited customization options

- May require additional add-ons for full functionality

Best For:

Small to mid-sized electronics manufacturers looking for an affordable and integrated ERP solution.

4. Oracle JD Edwards EnterpriseOne

Oracle JD Edwards EnterpriseOne is a powerful ERP solution designed for medium to large enterprises, including those in the electronics manufacturing industry. It offers extensive functionality across financials, supply chain management, production, etc. With flexible deployment options and a wide range of industry-specific features, JD Edwards EnterpriseOne helps manufacturers optimize their operations and drive growth.

Top 5 Features:

- Comprehensive supply chain management

- Advanced financial and accounting tools

- Flexible production scheduling

- Integrated asset lifecycle management

- Industry-specific compliance features

5 Benefits:

- Improved supply chain and inventory control

- Improved financial accuracy and reporting

- Optimized production schedules and efficiency

- Better management of assets and resources

- Compliance with industry standards and regulations

2 Cons:

- High cost of implementation and maintenance

- Steep learning curve for new users

Best For:

Medium to large electronics manufacturers requiring a robust, enterprise-grade ERP solution with extensive features.

5. Microsoft Dynamics GP

Microsoft Dynamics GP is a well-established ERP solution that caters to small and mid-sized businesses, including electronics manufacturers. It provides strong financial management capabilities alongside inventory, production, and sales modules. Dynamics GP is known for its ease of integration with other Microsoft products, making it a versatile option for businesses already using the Microsoft ecosystem.

Top 5 Features:

- Comprehensive financial management

- Inventory and supply chain management

- Production and operations control

- Integration with Microsoft Office and other tools

- Reporting and business intelligence

5 Benefits:

- Strong financial oversight and accuracy

- Improved inventory and supply chain visibility

- Streamlined production processes

- Seamless integration with Microsoft products

- Improved reporting and data analysis

2 Cons:

- Limited scalability for very large enterprises

- Requires on-premises infrastructure for some features

Best For:

Small to mid-sized electronics manufacturers looking for a reliable ERP solution that integrates well with Microsoft products.

6. HashMicro

HashMicro offers a versatile cloud-based ERP solution tailored for various industries, including electronics manufacturing. It features modules for inventory management, production planning, sales, and customer management, all integrated into a single platform. HashMicro’s ERP is known for its ease of use, quick implementation, and scalability, making it a suitable choice for growing businesses.

Top 5 Features:

- Real-time inventory management

- Automated production scheduling

- Sales and customer relationship management

- Integrated accounting and financials

- Cloud-based platform with easy access

5 Benefits:

- Improved inventory tracking and accuracy

- Better production planning and efficiency

- Improved customer management and sales tracking

- Streamlined financial processes and reporting

- Scalable solution that grows with your business

2 Cons:

- Limited industry-specific features

- May require customization for advanced needs

Best For:

Growing electronics manufacturers seeking a user-friendly and scalable cloud ERP solution.

7. eresource Xcel ERP

eresource Xcel ERP is a specialized solution designed for the manufacturing sector, including electronics. It offers a comprehensive suite of tools for managing production, inventory, procurement, and sales. eresource Xcel ERP is known for its affordability and quick implementation, making it an attractive option for small to mid-sized manufacturers looking to improve their operational efficiency.

Top 5 Features:

- Production planning and control

- Inventory and procurement management

- Sales order processing

- Real-time reporting and analytics

- Customizable dashboards

5 Benefits:

- Improved production planning and efficiency

- Better inventory and procurement control

- Streamlined sales processes and order management

- Improved decision-making with real-time data

- Affordable and quick to implement

2 Cons:

- Limited advanced features for large enterprises

- May require additional customization

Best For:

Small to mid-sized electronics manufacturers looking for an affordable and effective ERP solution.

8. Epicor

Epicor is a comprehensive ERP solution designed for mid-sized to large manufacturers, including those in the electronics industry. It provides robust tools for managing production, supply chain, inventory, and financials. Epicor’s flexible architecture allows for extensive customization, making it suitable for complex manufacturing environments with unique requirements.

Top 5 Features:

- Advanced production management

- Supply chain and inventory control

- Financial management and reporting

- Customizable workflows and processes

- Integrated CRM and sales management

5 Benefits:

- Improved production efficiency and control

- Improved supply chain visibility and management

- Streamlined financial processes and accuracy

- Flexibility to customize workflows

- Better customer relationship management

2 Cons:

- High implementation costs

- Complexity may require extensive training

Best For:

Mid-sized to large electronics manufacturers with complex needs and a focus on customization.

9. Plex

Plex is a cloud-based ERP solution designed specifically for manufacturers, offering end-to-end functionality across production, inventory, supply chain, and quality management. Known for its real-time visibility and agility, Plex enables manufacturers to respond quickly to changing market demands. It’s particularly suited for electronics manufacturers that require flexibility and scalability in their operations.

Top 5 Features:

- Real-time production monitoring

- Integrated quality management

- Supply chain and inventory control

- Cloud-based platform with scalability

- Detailed reporting and analytics

5 Benefits:

- Increased agility with real-time insights

- Improved quality control and compliance

- Better inventory and supply chain management

- Scalable solution that grows with your business

- Improved decision-making with detailed analytics

2 Cons:

- May require extensive customization

- Subscription costs can be high for small businesses

Best For:

Electronics manufacturers looking for a flexible, cloud-based ERP solution with strong real-time capabilities.

10. Cetec ERP

Cetec ERP is a modern, web-based ERP solution designed for small to mid-sized manufacturers, including those in the electronics industry. It offers a complete suite of tools for managing production, inventory, quality control, and financials. Cetec ERP is known for its affordability, ease of use, and quick implementation, making it an excellent choice for companies seeking a cost-effective ERP solution.

Top 5 Features:

- Web-based platform with easy access

- Production and inventory management

- Integrated quality control tools

- Financial management and reporting

- Customizable dashboards

5 Benefits:

- Cost-effective solution for small to mid-sized businesses

- Improved production and inventory control

- Improved quality management and compliance

- Quick and easy implementation process

- Accessible from anywhere with a web-based platform

2 Cons:

- Limited advanced features for larger enterprises

- May require additional customization for specific needs

Best For:

Small to mid-sized electronics manufacturers looking for an affordable ERP solution.

Top Features in ERP for Electronics Manufacturing

Focusing on key features like BOM management, supply chain, production planning, and quality control can greatly improve your business. This section highlights core features that increase efficiency in your organization.

Bill of Materials (BOM) Management

BOM management provides a detailed list of all components and materials needed to make products. It helps track items better, reduces waste, and makes cost estimation more accurate. With better BOM management, updating the production process is easier.

Supply Chain Management

Good supply chain management helps suppliers, materials, and logistics work together smoothly. ERP systems provide real-time visibility, letting you quickly adjust to market changes and maintain the right inventory levels. This optimizes supply chain operations, avoiding delays and ensuring products are delivered on time.

Production Planning and Scheduling

Production planning is key to running a factory well. An ERP system helps schedule production to match demand forecasts. This reduces downtime, reduces unused resources, and keeps production on track with quality and delivery times.

Quality Control and Compliance

Quality control is vital for making products that meet standards. An ERP system brings quality control into production, allowing ongoing checks and compliance. This proactive approach lowers risks and keeps customers happy.

Real-Time Analytics and Reporting

Real-time analytics let you make smart decisions with accurate data. Detailed reports give insights into production, inventory, and quality. Using these insights, you can quickly adjust strategies to improve operations.

| Feature | Description | Benefits |

| BOM Management | Tracks materials and components required for production. | Reduces waste and improves cost accuracy. |

| Supply Chain Management | Facilitates coordination with suppliers and logistics. | Improves efficiency and prevents delays. |

| Production Planning | Aligns production with demand forecasts. | Reduces downtime and optimizes resource use. |

| Quality Control | Ensures products meet industry quality standards. | Mitigates risk and maintains customer satisfaction. |

| Real-Time Analytics | Provides insights into production metrics. | Enables informed decision-making and adapts strategies. |

Choosing ERP for Electronics Manufacturing

Choosing the right ERP system is key to making your electronics manufacturing run smoothly. You need to think about project management, cost tools, and a good plan for implementing the ERP.

Project Management Capabilities

Look at the ERP system's project management features. Make sure it has tools for managing timelines, resources, and the project's scope. A strong project management part can make processes smoother, helping your team hit deadlines and produce quality products.

Cost Analysis and Manufacturing Simulations

Include cost analysis and manufacturing simulations in your ERP choice. These tools help you make accurate financial forecasts and check efficiency before spending resources. Ensure the ERP supports financial planning, which is key to profitability.

Implementation Strategy Planning

Having a clear ERP implementation plan ensures a smooth changeover. Check the ERP's planning frameworks to see if they fit your business needs. A well-planned implementation can lower risks and make the ERP success more likely for electronics manufacturing.

What is the Cost of ERP for Electronics Manufacturing

Understanding the cost factors of ERP systems helps you set a realistic budget. The costs can change a lot because of factors like features, deployment methods, and the type of license you get.

Here are the main ERP cost factors to think about:

- Implementation Costs: This includes the initial setup, making the software fit your needs, and moving your data over.

- Licensing Fees: These are a big part of the cost and can change based on how many users or modules you need.

- Maintenance and Support: These are ongoing costs for keeping the system up to date, fixing problems, and helping users.

- User Fees: Some systems charge extra for each user, which can really affect the cost.

- Training Expenses: These are the costs of teaching your employees how to use the new system.

- Integration Costs: These are possible extra costs for linking the ERP system with your current tools and platforms.

When planning your ERP budget, consider all these factors. A careful look will help you use your resources well and avoid unexpected costs.

Kohezion: An Efficient ERP Solution for the Electronics Manufacturing Industry

Kohezion is a top choice for an efficient ERP solution in electronics manufacturing. It offers features made just for the industry's needs and can be customized to fit your business perfectly.

The Kohezion features help streamline work, enabling teams to work better together and do more. It has tools for managing projects, tracking compliance, and monitoring inventory, which are key for quality and efficiency.

Kohezion is big on following the rules. It has built-in compliance tools, helping manufacturers meet standards. This lowers risks and builds trust, especially for companies looking to grow.

Many electronics companies have seen great results with Kohezion ERP. They use its advanced analytics to make smart choices, which leads to better planning and resource use.

Conclusion

Choosing the right ERP solution is key to improving your electronics manufacturing operations. We've shown how ERP systems help manage inventory and improve quality. They also make production smoother and offer strong tools for managing money and analyzing data in real-time.

Think about what features are most important for your business, like managing Bills of Materials and optimizing supply chains. The best ERP will fit your needs and help you make better decisions and work more efficiently.

Investing in a good ERP system is a smart move for your company. Look for an ERP that meets your needs now and prepares you for the future in this fast-changing field.

If you're ready to explore how Kohezion can meet your specific ERP needs, contact us today to learn more about how we can help your business grow.

Start building with a free account

Frequently Asked Questions

When migrating to a cloud-based ERP, consider data security, integration with existing systems, and user training. Ensure that your data is secure and compliant with industry regulations. Also, make sure the ERP can integrate with your current software and that your team is adequately trained.

ERP systems provide real-time tracking and traceability of components, streamlining the process of managing product recalls. This allows manufacturers to quickly identify and isolate defective products. The system also helps in maintaining compliance with industry regulations during the recall process.

ERP systems optimize resource usage, reduce waste, and ensure compliance with environmental regulations. They help monitor energy consumption, manage recycling processes, and track the use of sustainable materials, leading to more efficient and eco-friendly manufacturing operations.

ERP systems should be updated regularly to ensure they remain secure and functional. Updates often include security patches, new features, and improvements that can improve performance. Follow the vendor’s recommended update schedule to keep your ERP running smoothly.