Understanding how ERP inventory management software works can help you optimize your inventory processes and improve your business efficiency. In this article, we'll explore everything you need to know about using ERP software to manage your inventory effectively, from its importance in streamlining operations to its key features and benefits.

What Is ERP Inventory Management?

ERP Inventory Management refers to processes and systems that control inventory levels, orders, sales, and deliveries through an integrated software application. It's part of a larger Enterprise Resource Planning (ERP) system, which coordinates all aspects of a company's operations on a single platform. ERP inventory management systems enable real-time data access and decision-making, facilitating more efficient inventory management.

ERP inventory management interlinks with other business functions like finance, production, and sales, ensuring that each department understands inventory levels and requirements. This ensures businesses can anticipate needs, streamline operations, and reduce waste while satisfying customer demands more effectively.

What Is ERP Inventory Management Software?

ERP inventory management software is a platform designed for monitoring and managing the storage, allocation, and flow of goods within a company. It's a specialized tool within a broader Enterprise Resource Planning system that synthesizes inventory data with other business operations. This software tracks product quantities, orders, and stock levels in real-time, providing a bird's eye view of a business's inventory landscape.

With ERP inventory management software, you can automate procurement, streamline warehouse operations, and ensure timely product deliveries. It is also adaptable to your growing business needs and capable of scaling with you into new markets and product lines without the need for costly system overhauls.

Why Do You Need an ERP to Manage Your Inventory?

An ERP system helps you understand the entire ecosystem of your product flow. Managing inventory manually or with disjointed systems becomes chaotic with growing customer bases, diversified product lines, and expanded market reach. You need an ERP because it enables you to keep up with the increasing complexity and scale of inventory management seamlessly and efficiently.

With an ERP, you can automate repetitive tasks, ensuring that your business isn't bottlenecked by manual processes and that your employees can focus on high-value activities. The system can predict and respond to low stock levels, manage orders across multiple channels, and significantly reduce the risk of overstocking or stock-outs.

Plus, it minimizes the need for significant system upgrades, even as your business grows and changes. According to statistics, inventory management ERP can reduce inventory requirements by up to 30% and lower operation costs by 45%.

An ERP for inventory management enables you to make smarter decisions and satisfy customer demand without unnecessary overheads, putting you ahead of the competition.

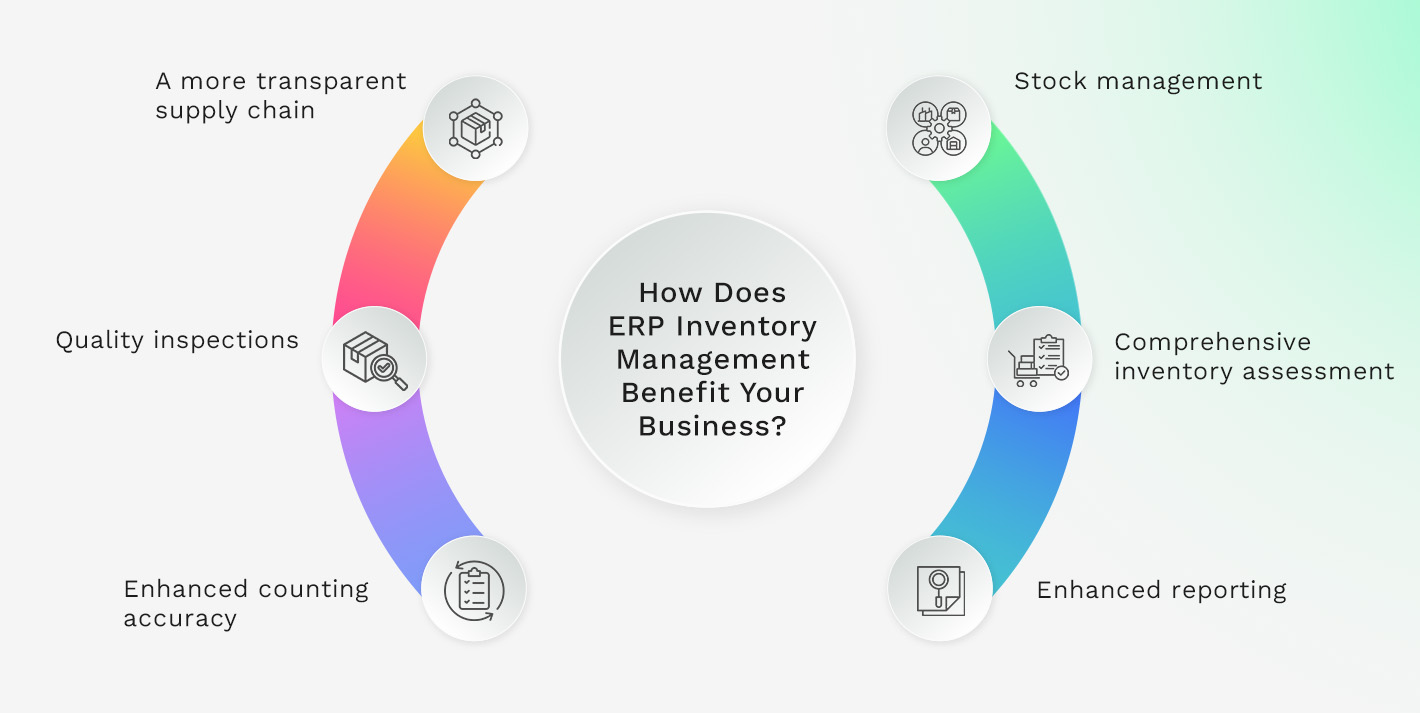

How Does ERP Inventory Management Benefit Your Business?

Your teams and departments can access inventory information with an ERP inventory management system. This leads to faster order fulfillment, decreased stockouts, and lower holding costs. The benefits of using an ERP inventory management system include the following:

A more transparent supply chain

75% of supply chain management professionals want to improve their inventory management practices. ERP software breaks down silos between departments, ensuring that everyone has access to the same information.

Transparency also improves collaborations with suppliers and distributors, giving them secure access to relevant parts of your ERP system. This means problems are flagged earlier, and there are fewer opportunities for errors. The result is a more resilient supply chain capable of adjusting to disruptions and consistently meeting customer demand.

Quality inspections

ERP inventory management systems automate and streamline quality inspections with built-in logic or rules. The software can assess whether products meet established quality and safety specifications and generate notifications for non-compliant items, ensuring that you adhere to standards. This feature particularly benefits industries with regulatory compliance requirements. It also makes it easy to generate detailed traceability reports and conduct audits.

Enhanced counting accuracy

Inventory accuracy in US retail operations is 63% on average. ERP provides real-time data, taking snapshots of inventory levels at the beginning of each count. Alerts are generated if there's activity during a count, allowing you to adjust promptly and keep accurate records.

Such precision in counting provides data that informs your purchasing, sales, and forecasting. Improved counting accuracy ensures that inventory records match actual stock, minimizing discrepancies that lead to financial losses or stock-outs. The result is a reliable, consistent inventory management approach supporting robust business processes.

Stock management

An ERP system helps maintain the right stock levels—not too much to tie up capital in excess inventory and not too little to risk stock-outs and lost sales. ERP constantly monitors stock levels and automatically triggers replenishment orders based on pre-defined thresholds.

The system can also give you insights into product performance, pointing out which items are selling well and which are moving slower, enabling you to make data-driven decisions. ERPs can manage different stock types across multiple locations, preserving the optimal amount of inventory everywhere and every time.

Comprehensive inventory assessment

ERP software integrates inventory data with other operational insights to provide a 360-degree view of your inventory's health. It evaluates metrics like turnover rates, carrying costs, and order accuracy.

This full-spectrum analysis is invaluable for strategic planning. You can identify trends, foresee potential issues, and capitalize on opportunities in real time. An ERP makes it possible to assess the impact of inventory decisions on other business areas, creating a holistic strategy that aligns with your business objectives. This improves your decision-making and ensures that your inventory practices support the productivity and profitability of your entire operation.

Enhanced reporting

Enhanced reporting capabilities turn data into a strategic asset. The system uses real-time data to auto-generate intricate reports about your inventory performance. You can explore analyses on sales trends, inventory turnover, and even seasonal demand forecasts.

Visual reports, such as charts, graphs, and heat maps, make data more digestible and uncover patterns and insights that might be overlooked in traditional spreadsheets. From daily summaries to comprehensive year-ends, the level of detail is customizable, ensuring stakeholders receive the tailored information they need. These reports can also reinforce audit capabilities, ensuring you're prepared for financial scrutiny.

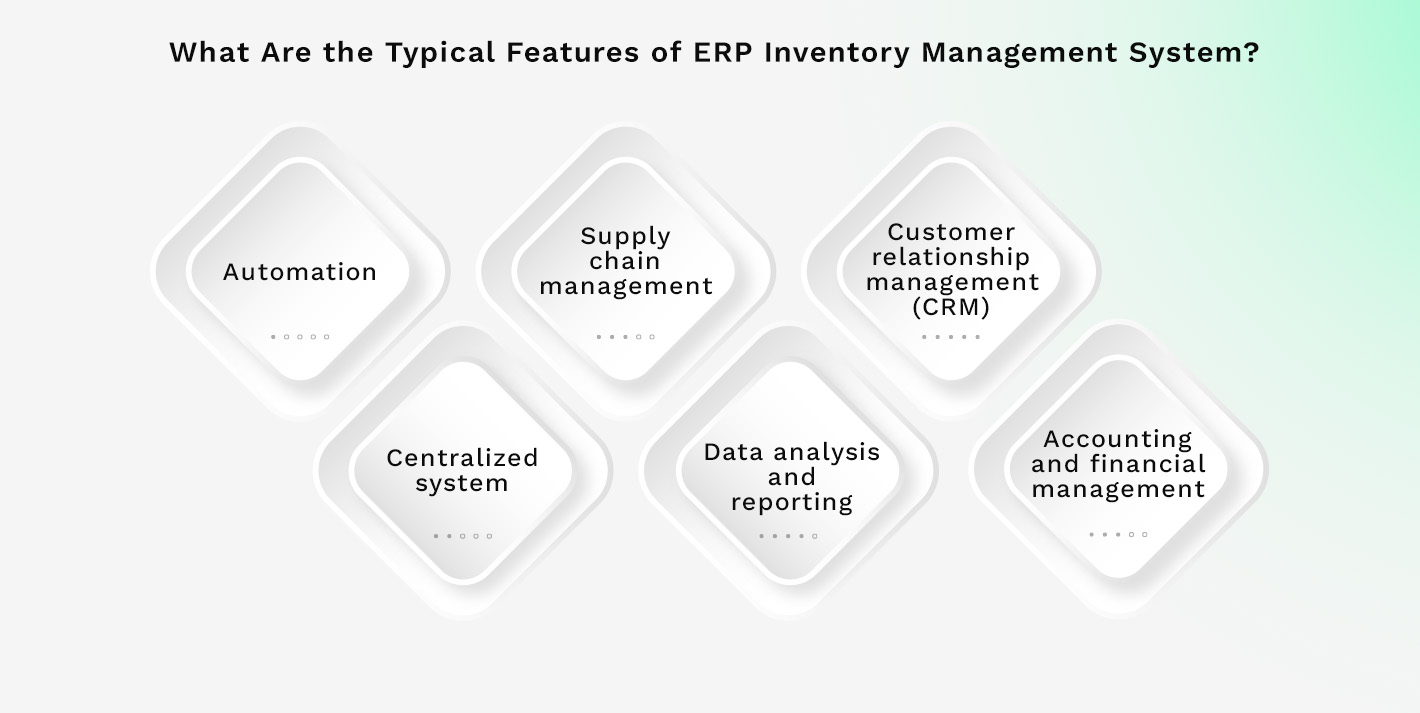

What Are the Typical Features of ERP Inventory Management System?

This section lists the essential features of an ERP inventory management system.

Automation

Automation is a standout feature of ERP inventory management systems that drives efficiencies across the entire inventory lifecycle. Automating tasks such as order processing, stock level monitoring, and reordering helps minimize human intervention, saving time on repetitive tasks and reducing the potential for human error.

Centralized system

A centralized system in ERP inventory management means you have a single source of truth for all your inventory data. This consolidates information across various departments and locations, improving visibility and coordination.

Supply chain management

Supply chain management within an ERP inventory management system helps manage your entire supply network, including procurement, production, shipping, and everything in between. This ensures that procurement is aligned with production needs, reduces lead times, and improves customer satisfaction.

Data analysis and reporting

Data analysis and reporting in ERP inventory management convert raw data into actionable insights. With sophisticated analytical tools built into ERP systems, you can easily dissect and interpret vast amounts of inventory data. This helps you identify inefficiencies and opportunities and improves the accuracy of forecasts and planning.

Customer relationship management (CRM)

Customer Relationship Management (CRM) within an ERP inventory management system leverages detailed insights into customer purchase histories and preferences, helping you build stronger connections. This enables personalized marketing and sales strategies to increase conversion rates, customer satisfaction, and customer loyalty.

Accounting and financial management

Accounting and financial management within ERP inventory management systems ensure that every dollar in your inventory is tracked and accounted for. This provides an accurate reflection of inventory's financial impact on business performance, simplifies tax reporting and compliance management, and enables you to plan with relevant financial data.

Overcoming the Challenges of ERP Inventory Management

Traditional inventory management has pitfalls that can negatively impact your business’s growth and efficiency. Here are the most common challenges and how ERP systems can help you.

Complexity and Customization Required in ERP Systems

Inventory management tends to be complex. Standard inventory systems try to provide a universal solution for businesses, but this doesn’t work because no two organizations are exactly alike.

Standard inventory management software can also be slow to operate, especially cloud-based ones that rely on steady and speedy internet connections. This may cause severe issues if you depend on accurate reporting and quick, real-time location.

ERP inventory management systems allow customization. You can implement updates and adjustments to the system to better suit your requirements. While IT and development teams are often needed to implement these upgrades, many modern ERP systems, such as Kohezion, offer customers low- and no-code platforms.

Managing Inventory Across Multiple Channels

Managing inventory across multiple channels can be daunting, especially if you’re not using the right inventory management system to support your scaling.

ERP inventory management systems help you manage inventory from multiple channels. They enable real-time access to accurate information on the go. You can also avoid data siloes around inventory, giving your finance and administrative teams full access to any information relating to inventory.

Dealing With Dead Stock

Dead stock (obsolete inventory) is another challenge that traditional inventory management often fails to solve. These are stocks that are either unused or unsold, making them unprofitable.

With an ERP inventory management system, you can track dead stock. You also gain full visibility on product manufacturing and expiry dates. Automation features also alert you when a stock becomes obsolete.

ERP inventory management systems also automate stock workflows, avoiding human errors or oversight. Such systems also automate your order and reorder points, and robust data analytics allow you to make data-driven decisions about your inventory.

How to Choose the Right ERP Inventory Management Software for Your Organization?

Choosing the right ERP inventory management software for your organization can be challenging. Many options exist in the market, but they may not always suit your business requirements. To help you choose the right system, consider the following steps:

Identifying Your Intended Outcomes

When choosing an ERP inventory management system, consider your organization's and stakeholders' needs and goals. Analyze trends, determine opportunities, consider resources, and pinpoint your core competencies.

Your long-term objectives will determine the best ERP software you need. It should align with these objectives and provide actionable insights to improve your inventory strategy for the long haul.

Scoping Out Your Project

To measure success, determine the key metrics you must feed into the ERP inventory management system. Define the data sources you’ll use, and establish which users — such as suppliers — will need access to the system. Also, create a list of necessary features and functionalities to help you achieve your goals.

Developing an ROI analysis

Developing an ROI (Return on Investment) analysis is a strategic move to ensure that the ERP inventory management system you're considering will be a financially sound investment for your business. It provides a clear financial framework to justify the ERP investment, helps in setting realistic expectations about the financial gains from the ERP system, and supports strategic decision-making.

Conducting a Vendor Analysis

When you’ve established goals and scope out the project, create a vendor list and analyze each one on that list. Find systems that meet your needs. Review similar businesses and check how the ERP system has helped them achieve their goals.

Ask questions about the system’s flexibility, integrations, and scalability. Seek answers from companies within your industry. It’s also wise to ask about any learning curve necessary to maximize your system usage.

Other key points to research include:

- The cost of the system. Ask about any free versions you can use for testing and get a breakdown of its pricing (upfront, monthly, custom pricing, etc.).

- Implementation speed. Consider how long it will take for you to implement and adapt to the ERP system. Ask about maintenance.

- From there, review the system and determine if it truly aligns with your business needs. It’s also a good idea to create an implementation roadmap.

Build an Efficient ERP Inventory Management System with Kohezion

Looking for an efficient ERP inventory management system can be overwhelming. However, it’s a wise investment considering all the benefits you can get. You’ll achieve streamlined workflows and position yourself for better scalability while saving money and managing inventory effectively.

Kohezion offers all of that and more. We create robust ERP inventory management systems that fit your business needs. Book a training session with Kohezion today to empower your team and take control of your inventory.

Conclusion

Mastering ERP inventory management can transform your business, streamlining your operations and paving the way for scalability and growth. From improving supply chain transparency to leveraging powerful data analysis tools, ERP systems are a strategic investment in your company's future.

With diligent planning, a focus on key outcomes, and the right partner in vendors like Kohezion, you can navigate the complexities and harness the full power of ERP inventory management. Optimizing your inventory processes will translate into tangible benefits across your organization, from financial savings to customer satisfaction.

Start building with a free account

Frequently Asked Questions

ERP software can benefit any business managing a supply chain, including those in manufacturing, retail, healthcare, distribution, and non-profit to education sectors. It's especially useful for companies looking to optimize inventory control, reduce waste, and streamline operations.

ERP inventory management offers real-time tracking, automation, and integration with other business processes. Unlike traditional methods, which tend to be manual, isolated, and error-prone, ERP systems provide a cohesive, accurate, and efficient approach to managing inventory across the entire enterprise.

ERP inventory software provides accurate, real-time data and analytics to improve your decision-making processes. It offers insights into inventory trends, demand forecasting, and business performance, enabling more informed, strategic choices and quick adaptation to market changes.

Your business needs ERP inventory management software if you're experiencing challenges with tracking inventory, fulfilling orders accurately, or managing supply chains efficiently. It's beneficial if you aim to scale operations and require real-time, integrated data for better decision-making.

Yes, an ERP inventory management system can be highly customized. These systems can adapt to support specific business processes, reporting needs, and user roles to ensure they meet the unique requirements of your business operations.