Did you know that about 83% of organizations use a WMS.? Knowing the cost of a Warehouse Management System (WMS) is key to your business's success. The cost of WMS can vary a lot, depending on how you deploy it and your business's specific needs. Understanding these costs helps you make smart choices when setting your budget for WMS, allowing you to meet your specific operational goals.

What is a Warehouse Management System

A Warehouse Management System (WMS) is software that makes warehouse operations smoother. It offers a full set of features, like managing inventory and tracking stock levels. A WMS gives you the tools needed for fast order fulfillment and better logistics management.

It has features like real-time inventory tracking, managing goods coming in and going out, and packing orders. This inventory system makes sure goods move well in and out of your warehouse. It cuts down on mistakes and makes operations more efficient.

Using a WMS helps businesses improve their warehouse work and make better decisions about inventory and orders. Investing in this software helps manage resources better and serve customers well.

Why is a Warehouse Management System Important

Using a Warehouse Management System (WMS) helps increase efficiency and accuracy and makes customers happy. A WMS tracks inventory levels well, reducing mistakes and making things more reliable.

WMS makes things run smoother, ensuring deliveries are on time. It optimizes picking and shipping, leading to better logistics management and improving order fulfillment rates. This is a big part of the benefits of warehouse management.

As your business grows, a WMS can handle more work without a problem. It lets you keep up with changes in your operations without losing quality or speed.

Knowing the value of a WMS can help your business improve, meet customer needs, and stay ahead in a fast-changing market.

Benefits of a Warehouse Management System

Using a Warehouse Management System (WMS) brings many benefits to your operations, which results in increased warehouse efficiency and better performance.

Space Optimization

A good WMS maximizes storage space. It offers advanced layout designs and tracks inventory, which means you can store more without needing more space, saving money and improving efficiency.

Reduced Costs

A WMS makes processes smoother and more automated, which results in reduced costs. It reduces waste and increases productivity. This leads to lower expenses and better financial health.

Inventory Tracking

A WMS's big plus is its ability to accurately track inventory. This helps manage stock levels well, avoiding too much or too little stock, which improves your warehouse's performance.

Efficient Labor Management

Managing workers is easier with a WMS. It assigns tasks based on how well employees do their jobs. This helps you better manage your team, making them more productive and saving on labor costs.

Streamlined Supply Chain

A WMS shares data with all stakeholders, leading to smoother operations, fewer delays, and quicker responses to market needs.

Internal Automation Advantage

Automation is key in warehouse management systems. It reduces manual work, letting your team focus on important tasks. This makes your operation more agile and ready to handle challenges.

Efficient Shipment Handling

A WMS makes handling shipments more efficient. It streamlines processes for consistent and accurate deliveries. This increases customer satisfaction and strengthens your market position.

Better Customer Service

Quick and precise order fulfillment improves customer service. With up-to-date data, you can keep customers informed about their orders, which builds trust and loyalty.

Continuous Improvement

A WMS encourages ongoing improvement in your operations. It helps identify areas for improvement, allowing you to refine processes. This keeps productivity high and benefits your operations over time.

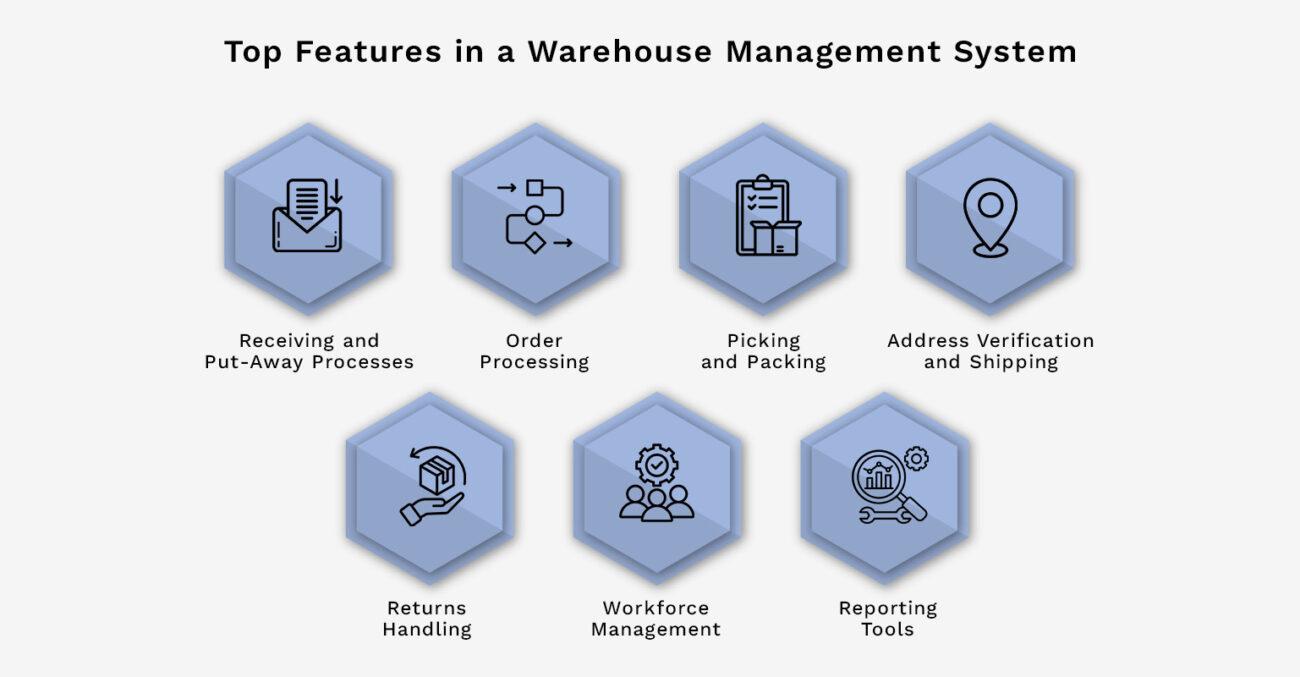

Top Features in a Warehouse Management System

A Warehouse Management System (WMS) has many key features that improves your warehouse operations. These essential WMS functionalities change how you handle inventory and streamline processes.

Receiving and Put-Away Processes

WMS features make receiving and putting away items quick and efficient. This means products are stored well, making it easier to find them later.

Order Processing

Order processing helps fulfill orders smoothly. It works well with your sales channels, making managing customer orders easy and helping you meet demand accurately.

Picking and Packing

Picking and packing features make picking routes better and packing more accurately, increasing productivity and customer happiness.

Address Verification and Shipping

Address verification and shipping features check shipping details for accuracy. This important WMS function works with logistics partners to ensure timely deliveries and fewer errors.

Returns Handling

Handling returns well means you can manage them smoothly. This feature helps return returned stock to inventory, keeping inventory levels accurate and making customers happy.

Workforce Management

Tools for managing your team track labor productivity and employee performance. This helps you use your resources better, making sure your operations are efficient.

Reporting Tools

Strong reporting tools give insights into warehouse performance, helping you make smart decisions for ongoing improvement and better business operations.

How Much Does a Warehouse Management System Cost

The price of a WMS depends on how you choose to deploy it. You can choose from cloud-based or on-premises options. Each has its costing method that can affect your budget.

Cloud-Based Pricing

Cloud-based systems use a subscription model. On average, you'll pay about $167 per user monthly for basic services. Adding more features or users will raise the cost. But, the initial costs are lower, making it great for businesses wanting flexibility in their spending.

Over time, the total cost may increase with more users. Yet, many companies find this model easy to manage and grow with.

On-Premises Pricing

On-premises pricing means a higher upfront cost. Basic setups start around $2,500, but top-tier systems can go over $200,000. These systems often require extensive custom work and ongoing support.

Even with higher initial and maintenance costs, on-premise solutions can be cheaper in the long run. This depends on your company's size and needs.

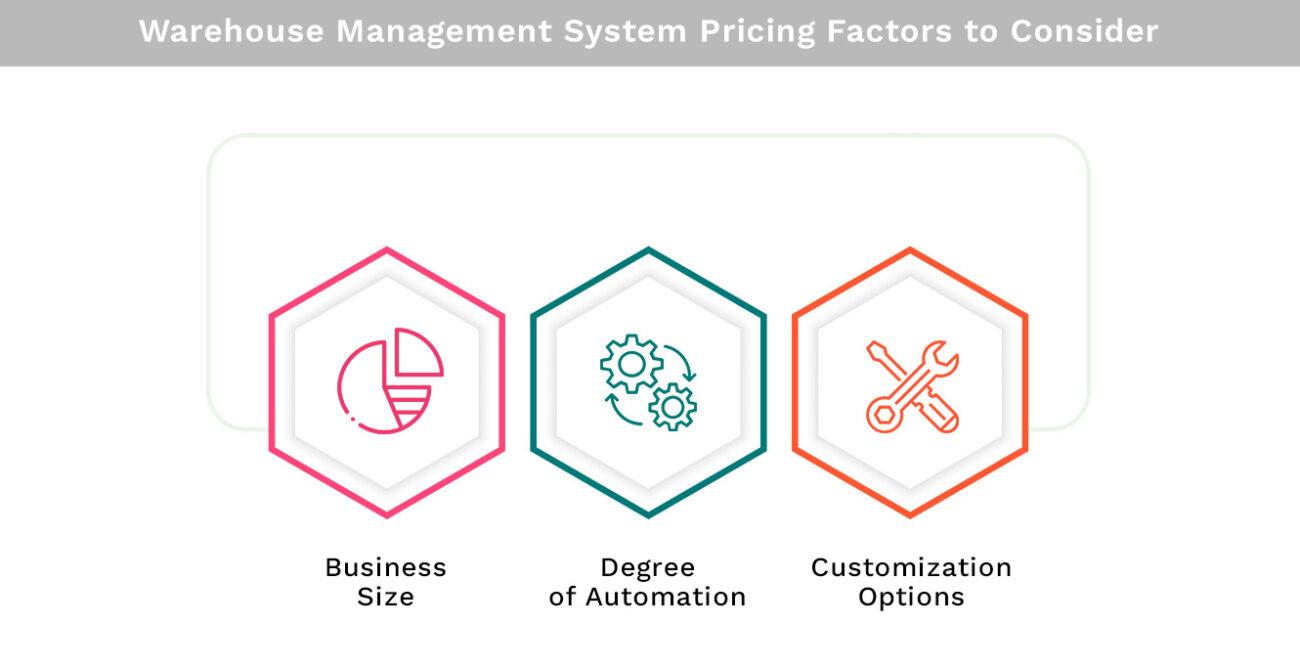

Warehouse Management System Pricing Factors to Consider

Several elements affect the cost of a Warehouse Management System (WMS). Knowing these factors helps you make smart choices when planning your investment.

Business Size

The size of your company plays a big role in choosing a WMS. Big operations need more complex systems to handle many inventory and transactions. This means higher costs. On the other hand, smaller businesses can opt for simpler solutions that are cheaper.

Degree of Automation

The automation level in your WMS affects its price. Automated features make processes faster and more efficient and reduce mistakes. However, they can be more expensive upfront. Consider what you need to decide on the right mix of automation and traditional methods.

Customization Options

Choosing customization means getting features that fit your specific needs. Custom solutions can make things easier to use and optimize for your business but they usually cost more than standard software. Figure out how much customization you need to set a budget and pick the right WMS for your goals.

Hidden Warehouse Management System Costs to Account for in Your Budget

Planning for a Warehouse Management System (WMS) means looking beyond the initial cost. Think about hidden costs that can affect your budget. Knowing these costs helps you prepare and avoid unexpected expenses.

Staff Training

Getting a new WMS often means a lot of training for your staff. This training usually takes 3-5 days and might need more sessions later. Your team must learn the system well to reduce mistakes and work better.

Infrastructure Upgrades

Upgrading your infrastructure is often needed, especially for systems you keep on-site. You might have to buy new servers, networking gear, or software licenses. These costs can add up fast and affect your budget.

IT Staff Resources

Don't forget to include the cost of your IT staff in your budget. The system will need ongoing maintenance, updates, and sometimes consulting fees. Having your IT team ready is a key cost that affects how well your operation runs.

Data Utilization

Using your WMS's data well is key to getting the most out of it. This might mean spending on analytics tools or training to understand the data better. Focusing on these areas can turn hidden costs into important investments that improve your operations.

How Can Kohezion Help with Warehouse Management?

Kohezion provides top-notch support for managing warehouses, aiming to increase efficiency. It offers specific WMS solutions for different business needs. The platform is easy to use, simplifying inventory management and order fulfillment, helping you improve your logistics operations.

Kohezion's features can easily fit with your current systems. This flexibility helps streamline your warehouse's workflow, making it more efficient. Kohezion also offers great customer support and training to help you fully use the platform. This ensures your team can make the most of automated warehouse management, leading to better productivity and happier customers.

Conclusion

When evaluating the cost of WMS, consider different deployment options and your business needs. Investing in a Warehouse Management System is a big step towards a better future for your operations. It's not just about the upfront costs.

Warehouse management systems improve your operations and customer service, help streamline your processes, and set your business up for success. It's important to consider all costs and potential savings to make a wise financial choice.

Having the right WMS can greatly improve productivity and accuracy. This means you'll have a stronger position in the market, making your business more resilient and adaptable. When picking a system, ensure it fits your business goals for the best results.

Contact us to learn how Kohezion can help optimize your warehouse operations.

Start building with a free account

Frequently Asked Questions

To calculate the ROI, compare the costs of implementing the WMS with its savings and benefits, such as reduced labor costs, improved accuracy, and faster processing times. Also, consider long-term gains like increased customer satisfaction and reduced errors.

Yes, some free warehouse management systems are available, but they may have limited features and scalability. These free options can be a good starting point for smaller businesses or those with simple needs.

Ongoing costs may include software updates, technical support, training for new staff, and potential system upgrades as your business grows. Make sure to factor these into your budget when planning for a WMS.