A single error in the supply chain process can lead to detrimental results not only for your supply chain but also for the entirety of your organization.

Luckily, ERP software options are available. These systems aim to help supply chain managers and other stakeholders streamline their workflows and achieve peak efficiency. It offers various features such as automation, data visibility, and more.

According to a study, around 82% of businesses achieved their expected ROI after implementing an ERP system. The same study said that businesses that were more aggressive in implementing ERP systems were more likely to achieve their expected ROI than those who weren’t as eager.

We'll buid your first application for you. At no extra cost.

Let us build your first business application for free. Go from an idea to an application in under 2 weeks.

ERP in Supply Chain Management

Supply chains consist of networks of processes and teams that turn raw materials into finished products. These networks typically consist of manufacturers, suppliers, retailers, distributors, and customers.

Managing these complex networks of entities can be a tough job. It involves planning, execution, control, and monitoring tasks. This is where ERP solutions are integral — they ensure you have a holistic view of your operations to improve your approach to supply chain management.

ERP solutions help prevent any disruptions to your supply chain management process. Such disruptions can have adverse effects on customer satisfaction ratings and result in huge losses. ERP makes the management process smooth and resilient, allowing you to always meet customer demands despite market fluctuations and customer behavior changes.

The software behind ERP solutions automates a diverse range of workflows and tasks. These include:

- Inventory and purchasing

- Customer relations and sales

- Production and order processing

- Finances and accounting

With a good ERP solution in supply chain management, you get a singular source of data relevant to all aforementioned workflows and processes. Feature-rich ERP products can also support various modes of operations and streamline the path of your products from supplier to warehouse and consumer.

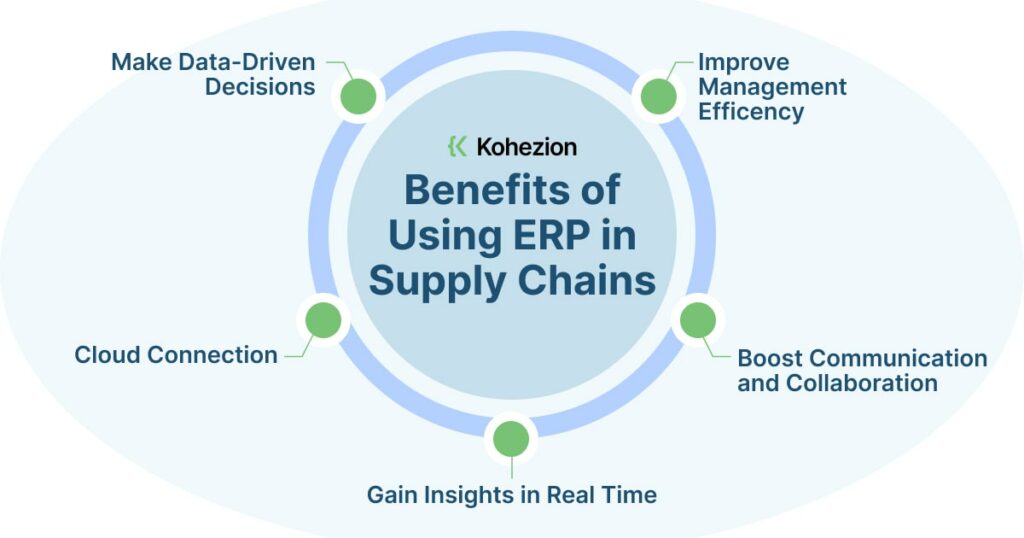

Benefits of Using ERP in Supply Chains

ERP solutions offer a wide range of benefits for supply chains. These benefits include:

- Improve Management Efficiency. ERP systems use automation to streamline supply chain management operations. The visibility they have across the entire chain enable stakeholders to make quick but informed decisions. These decisions help reduce costs in terms of logistics, manufacturing, and procurement.

- Boost Communication and Collaboration. ERP systems improve coordination between you and your team and vendors. When external suppliers connect to your ERP, you can collaborate more effectively to meet established goals while avoiding bottlenecks. For instance, you can instantly recognize when supplies are low, thus ensuring resource availability.

- Gain Insights in Real Time. ERP systems provide real-time metrics that you can use to constantly improve your chain’s effectiveness. This also lets you address operational disruptions and market changes more quickly. At the same time, you position your business to focus on growth.

- Make Data-Driven Decisions. With a good ERP system, you gain visibility to market data and real-time information about your business performance. As a result, you can make data-driven decisions and create better strategies around your resources. This allows you to target specific goals with better precision.

- Cloud Connection. ERP systems are available through the cloud. This gives you further benefits such as better security and mobility. Cloud-based ERP solutions are also accessible anywhere and anytime on mobile devices if you’re connected to the internet. This means you can take action quickly, which is often necessary in fast-paced supply chains.

How ERP Software Improves Supply Chain Efficiency

ERP software improves the efficiency of your supply chain, as it helps you address complex challenges in the face of the ever-evolving global supply chain. Here’s how ERP systems improve supply chain efficiency.

Supply Chain Planning

Planning makes up a huge portion of supply chain management. With an efficient ERP system, you gain a more accessible and flexible way to adjust the chain’s parameters in the planning stage when necessary.

For example, you can determine stock and inventory levels and optimize warehouse picking and resource management. This ensures that your production levels match demand and allows for on-time replenishment. You also:

- Create better work schedules

- Ensure replenishment dates keep up with demand levels

- Plan more accurate delivery dates

Inventory Management

If you retail across multiple channels, inventory management becomes a tough nut to crack. One error can disrupt the chain, resulting in delays and dissatisfied customers. Excess inventory may accumulate, increasing holding costs. It also consumes precious warehouse space.

Integrating an ERP system into your supply chain management gives you access to all inventory information. You can use this to maintain lean inventory. If you’re a supervisor, you can know precisely what resources are used for each shipment in real time.

Customer Relations and Deliveries

ERP systems are great for finding the most appropriate packaging methods and criteria for quality control. Moreover, you maintain a repository for shipments and delivery details.

Using an ERP system, you can record and track shipping processes. Updating and storing all information also happens automatically.

There’s more: your workforce and customers can also track orders and deliveries. The ERP system generates and sends invoices to customers when shipping orders. In other words, ERP for supply chain management allows for greater personalization in customer experience.

For example, you can offer made-to-order and configurable products. ERP solutions for supply chain management help you produce quality products faster while offering robust customer service.

What this means is you can achieve on-time deliveries, strengthen customer loyalty, and encourage repeat orders.

Evaluation and Maintenance

If you’re using multiple independent systems and workflows for supply chains, you may find it difficult to measure actual performance to your targets.

However, integrating ERP systems into supply chains gives you cross-platform access to all pertinent information — whether that’s from a financial, inventory, or manufacturing perspective.

You gain robust information organization and aggregation. With such capabilities, you can identify and resolve any discrepancies in the supply chain.

Performance evaluation and maintenance become easier. With a better ability to monitor, review, and change supply chain efforts, you can reduce the impact of any unexpected events.

Features to Look for in a Supply Chain Management ERP

When looking for a good ERP system to integrate into your supply chain management, consider the following features:

- Ease of Use. A good ERP for supply chain management should be easy to use. After all, it serves your entire organization and synchronizes your supply chain with your business operations. The ERP should have functions that users can utilize for shipping, receiving, production, accounting, and others.

- Costs. Traditional ERP systems used to be expensive. Their maintenance is also often costly, plus they don’t always deliver. Nowadays, though, cloud-based ERP solutions are available. Subscriptions to them cover operating costs like upgrades and storage. This means you have more power over your expenses and a better return on investment (ROI).

- Integration. Integrating ERP systems into your supply chain management can be daunting, especially when done manually. Bespoke integrations are good, but they may also be complex. Luckily, unified supply chain management and ERP solutions can have a common platform, where they can share the same data model. They work natively on said platform, integrating seamlessly.

- Data Model. ERPs and supply chain management solutions that share a common data model run from a single source of truth. This ensures data accuracy. At the same time, you achieve great team productivity — your work becomes more cost-effective, and you avoid any data losses or inaccurate information.

- Cloud or Local. Many companies still use local-hosted ERPs, but cloud-based ERP solutions are better because of their ability to connect every point in your supply chain more easily. Each node — from manufacturing business processes and data — is connected with others from anywhere in the world. Subsequently, you gain optimal visibility, allowing you to provide the necessary support and control.

5 Best ERP Systems for Supply Chain Management

If you’re looking for the best ERP systems for your business and supply chain goals, we’ve listed the top five best solutions you can try right now. We talk about their biggest selling points as well as the types of business they’re most suitable for — check them out:

1. Kohezion

Kohezion is an online database application builder where you can create apps without coding. Because of this, it’s a great platform for creating a custom ERP system. You can customize this database software and turn customer data into a robust relational database.

It sports useful automation features where you can eliminate time-consuming tasks while focusing on core business processes. This is a valuable function for supply chain managers who need automated searching, filtering, reporting, and other functionalities.

Moreover, creating a custom ERP system for supply chain management via Kohezion lets you hone in on the features that you truly need most. You can even evolve the resulting app as your business needs change. Plus, web apps are more stable, secure, and accessible than spreadsheets on local computers.

Kohezion also has built-in collaboration tools you can leverage for your team. Share data easily and customize access and permission so the right people can access the right information. Kohezion’s powerful dashboard is also accessible even through mobile devices, which adds another layer of convenience to your ERP processes.

2. Microsoft Dynamics 365

Microsoft Dynamics 365 is a cloud-based ERP system that has capabilities for financial management, CRM, customer service, business intelligence, operations, marketing, project service automation, commerce, retail, sales, talent, and more.

These applications are integrated into one end-to-end system. As a result, you can remove information silos and achieve greater information transparency. You can also run standalone applications if necessary.

What makes Microsoft Dynamics 365 a great ERP system for supply chain management? It’s a no-brainer: it’s part of the Microsoft ecosystem and mixes well with the Microsoft suite. This allows for easier integration and crossovers between programs such as PowerBI and Azure.

This ERP system is a great fit for small-to-medium-sized businesses and some divisions of larger companies or organizations.

3. NetSuite

NetSuite is one of the most popular ERPs in the world, and it features comprehensive management capabilities. For supply chain management, NetSuite offers built-in business intelligence capabilities alongside real-time reporting and analytics.

It’s perhaps most popular for its accounting solutions. It offers strong expense and revenue management features. You gain real-time visibility into your financial performance. You and your workforce also have full visibility into inventory.

NetSuite is also ideal if you prefer close collaboration with your team and vendors. It integrates seamlessly with CRM and e-commerce systems for a more robust end-to-end business process management.

Here’s more: NetSuite is an open system, meaning you can integrate it with third parties and other industry-specific solutions. NetSuite is currently used by over 24,000 customers in more than 200 countries.

4. Rootstock Cloud

Rootstock Cloud is an ERP system specifically made for manufacturing, distribution, and supply chain organizations. It features powerful inventory management, sales CRM, order management, engineering, planning, and other useful functionalities.

With Rootstock Cloud, you acquire centralized control over your end-to-end manufacturing system. Many users also praise the quick and easy customization features it offers, often deeming them as the ERP’s biggest selling point.

Rootstock Cloud is best if you’re already familiar with the Salesforce ecosystem. It’s written natively for the Salesforce platform and effectively fills in any gaps that Salesforce leaves behind.

Moreover, Rootstock Cloud supports engineer-to-order (ETO), configure-to-order (CTO), and project-based manufacturing. You can also keep your production in sync with sales, thanks to its powerful MRP engine for sales forecasting.

5. Plex Systems

The Plex ERP system is a comprehensive and versatile solution that you can leverage to manage supply chains in a breeze. You get robust features and a user-friendly interface — you can truly streamline business processes and optimize inventory management workflows.

Plex is flexible: the platform is rapidly evolving and provides automatically updated features and versions. You don’t have to deal with costly hardware or large capital outlay. As a result, you gain cost-effective implementation, integration, and deployments.

Plex’s customer database lets you store interactions, target close dates, quotes, and more. This makes it easier for sales reps to track pipelines. You can also set up workflows for managing requests for quotes (RFQs) and get insights into your reps’ performance.

Build a Robust Supply Chain with Kohezion ERP

If you’re looking to improve your supply chain management capabilities with an ERP unique to your business needs, use Kohezion. We help you create custom ERP software that fits your specific requirements. Enjoy full control and visibility over your supply chain activities using a robust platform made specifically for you. Try Kohezion today.

Frequently Asked Questions

ERP provides a comprehensive solution for optimizing supply chain components. A good ERP system contributes to several key aspects of supply chain management. These aspects include data management, process integration, inventory management, demand planning and forecasting, supplier relationship management, compliance and risk management, and data analytics and reporting.

ERP improves supply chain management as it provides real-time visibility into various aspects. It also integrates and automates business processes, optimizes inventory levels, provides tools for demand planning, and assists businesses in complying with industry regulations and standards. Valuable analytical, fulfillment, and supplier relationship tools are also available.

ERP systems for supply chain management are popular among organizations in a diverse range of industries. These include manufacturing, retail, distribution and logistics, automotive, and healthcare. Other industries that require excellent ERP systems include consumer goods, electronics and technologies, and food and beverage industries.

This depends on the complexity of the software and your familiarity with other similar systems. There should be sufficient support and training if the software in question is known to be complicated. Customizations, automation, process integrations, implementations, and updates are some of the most important ERP aspects to focus on learning when using ERP software for the first time.

ERP and SCM systems are related but distinct types of solutions. For one, ERP systems have a larger scope than SCM systems — they integrate and manage various business processes, while SCM systems focus on managing and optimizing supply chain processes. ERP systems are also used by a wide range of stakeholders within a business, while SCM systems are for users directly involved in the supply chain process. These include managers, procurement specialists, and logistics professionals.