Did you know that the pharmaceutical manufacturing market is expected to grow to an estimated $261.2 billion in 2024? This huge amount shows how vital good supply chain management is in the pharmaceutical industry. It's important to understand the big challenges that companies face, like following rules and keeping drugs safe during transport.

This article will explore the complex world of the pharmaceutical supply chain. We'll examine the main players and their major challenges. We'll also share top strategies for managing the pharmaceutical supply chain well. These strategies can help you improve your operations and ensure that medicines are safe and effective for patients.

What is Supply Chain Management in the Pharma Industry

Supply chain management is key for those working in the pharmaceutical industry. It's a complex network that moves medicines from research to patients. It involves suppliers, manufacturers, distributors, and healthcare providers working together.

At every step in the pharmaceutical supply chain, strict rules must be followed to keep patients safe and ensure medicines work well. Getting medicines to patients on time and efficiently depends on these steps. Adapting to new rules and market changes makes it tough for everyone involved. Yet, focusing on these areas helps keep patients safe and medicines effective.

Why is Supply Chain Management in the Pharma Industry Important

Supply chain management ensures that medicines reach patients on time, directly affecting patient care and health outcomes.

When you manage your supply chain well, you make it more efficient. This means lower costs and better performance for your operations.

Following rules helps keep the public and patients safe. A well-planned supply chain makes things run smoother. It also helps with new ideas and keeps you ahead in a fast-changing market.

So, putting effort into strong supply chain practices can change things for both companies and patients.

Key Players in the Pharma Supply Chain

The pharmaceutical supply chain has many important players. Each one plays a key role in ensuring medicines are safe and work well. Knowing about these roles helps us understand how complex the system is and why working together is vital.

Suppliers of Raw Materials

Raw material suppliers are key to drug production. They provide the basic parts needed for medicines, and their focus on quality ensures that the materials are safe and effective.

Pharmaceutical Manufacturers

Pharma manufacturers turn raw materials into finished drugs. They follow strict rules to ensure the drugs are safe and work as they should. Their work on new treatments helps bring people new health options.

Regulatory Bodies

Groups like the FDA ensure the supply chain follows safety rules. They set standards and watch over the industry, keeping everyone, from suppliers to pharmacies, in line with important safety rules.

Wholesale Distributors

Wholesale distributors connect manufacturers with pharmacies. They handle large orders and keep the flow of medicines smooth. Their work is key to pharmacies having the drugs they need quickly.

Pharmacy Benefit Managers

Pharmacy Benefit Managers (PBMs) help manage costs and ensure people can get the necessary drugs. They negotiate prices and manage lists of approved drugs, which affects drug affordability and accessibility.

Pharmacies

Pharmacies are the last step in the supply chain. They give medicines directly to patients. Pharmacists teach patients about their drugs, making sure they use them right.

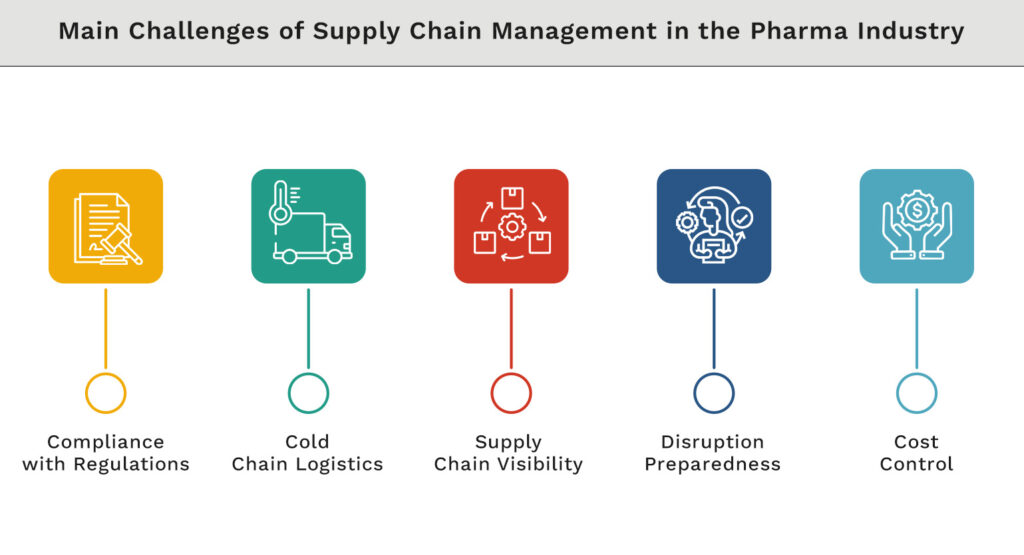

Main Challenges of Supply Chain Management in the Pharma Industry

Managing the pharmaceutical supply chain is tough. It faces many complexities that affect efficiency, following rules, and success in delivering important medicines. Knowing these challenges helps you prepare for and adapt to the industry's changes.

Compliance with Regulations

Following rules is a big challenge. Pharma companies must follow strict FDA guidelines. Breaking these rules can cause delays and increase costs, making it hard to deliver products on time. Companies must invest in training and systems to follow these rules and keep up with production.

Cold Chain Logistics

For many medicines, keeping products at the right temperature is key. This means managing a cold chain to prevent products from spoiling or losing their effectiveness. It's complex and requires careful planning to keep the product safe.

Supply Chain Visibility

Knowing what's happening in the supply chain is important for safety and efficiency. Tracking products from start to finish helps fight fake items. You need systems that give real-time data for quick decisions and keep the supply chain open.

Disruption Preparedness

Many disruptions, such as global issues and natural disasters, can affect the pharmaceutical supply chain. Being ready means having strong backup plans and finding different sources. Being proactive helps with staying strong and flexible.

Cost Control

Managing costs is tricky when making new products and keeping prices low. Pharma companies must deal with rising costs from following rules and shipping without raising prices too high. Good cost management can help keep profits up and ensure that medicines are affordable.

Supply Chain Management in the Pharma Industry Best Practices

Follow best practices to improve the pharma supply chain. These methods increase efficiency and help with sustainability in pharma. They also make operations run smoother.

Adopt Digital Solutions

Using digital tools like ERP systems and cloud platforms helps with communication. It also makes the supply chain more transparent, leading to quicker decisions and fewer mistakes.

It also makes it easier to keep track of medicines from the start to the end user.

Improve Inventory Management

Good inventory management keeps drugs available and reduces waste. Data analytics and real-time tracking ensure you have the right amount of stock. This balance helps avoid having too much stock.

Promote Collaboration

Good communication and partnerships help with following rules and getting ready for problems. Working with suppliers, distributors, and healthcare providers creates a strong network.

This network supports a strong supply chain.

Maintain Quality Control

Quality control is a must in the pharmaceutical industry. Ensure the high quality of everything from raw materials to finished products to prevent contamination and rule-breaking. This careful approach builds trust with consumers and healthcare workers.

Prioritize Sustainability

Putting sustainability first in pharma means choosing eco-friendly ways to make products and manage waste. These green efforts benefit the planet and improve your brand's image. They show you care about social responsibility and match what consumers want.

Address Pharma Supply Chain Management Challenges with Kohezion

In the pharma industry, solving supply chain issues requires new ideas. Kohezion leads the way in this change. They offer top-notch pharmaceutical supply chain software that clarifies the whole supply chain. This means you can keep track of your stock in real-time and lower the risks of not following rules and logistics problems.

Using Kohezion's tools helps teams work together better, ensuring everyone aims for the highest quality. It improves teamwork, allows you to deal with problems and changes in the market quickly, makes things run smoother, and makes sure patients get their medicines on time.

Conclusion

Supply chain management in pharma is complex, involving many stakeholders and rules. Everyone from suppliers to pharmacies is key to getting medicines to patients safely. Understanding this helps us see why a strong supply chain is vital.

It's important to tackle issues like following rules, keeping medicines cold, and seeing the supply chain clearly. Using digital tools, managing inventory well, working together, and focusing on being green are key to success.

As technology improves, using digital tools will help the pharmaceutical industry stay ahead. Working together will build trust and ensure that medicines are safe and available when needed.

If you’re looking for a reliable solution to strengthen your pharmaceutical supply chain, contact Kohezion today to see how we can help streamline your processes and ensure compliance.

Start building with a free account

Frequently Asked Questions

The main stages of the pharmaceutical supply chain include sourcing raw materials, manufacturing drugs, regulatory approval, distribution, and finally, delivering the products to pharmacies and patients. Each stage must be carefully managed to ensure the safety and effectiveness of the drugs.

Technology provides real-time tracking, improving stakeholder communication, and automating inventory management. Digital tools can help monitor temperature-sensitive shipments and ensure they remain within the required conditions. Using technology, companies can reduce errors, improve efficiency, and respond quickly to potential disruptions.

Regulatory bodies set the standards and guidelines that pharmaceutical companies must follow throughout the supply chain. They ensure that drugs are safe, effective, and properly labeled before reaching patients. Compliance with these regulations helps you avoid fines, delays, or product recalls.

Environmental challenges in the pharma supply chain include managing waste from production, reducing carbon emissions from transportation, and ensuring proper disposal of expired or unused drugs. Companies are increasingly focusing on sustainability practices to minimize their environmental impact. This includes using eco-friendly packaging and optimizing routes to reduce fuel consumption.

Global events like pandemics, natural disasters, or political instability can significantly disrupt the pharmaceutical supply chain. These events can lead to shortages of raw materials, production delays, and difficulties in distribution. Companies must have contingency plans to address these risks and maintain a steady supply of essential medications.